Thermosets Expand Opportunities in 3D Printing

The production of large-scale, 3D-printed thermoplastic composite parts has proved that additive manufacturing (AM) can reduce the time, material and labor required to make tooling and other products. But these thermoplastic-printed parts have limitations; for example, they don’t hold up well in high-heat applications.

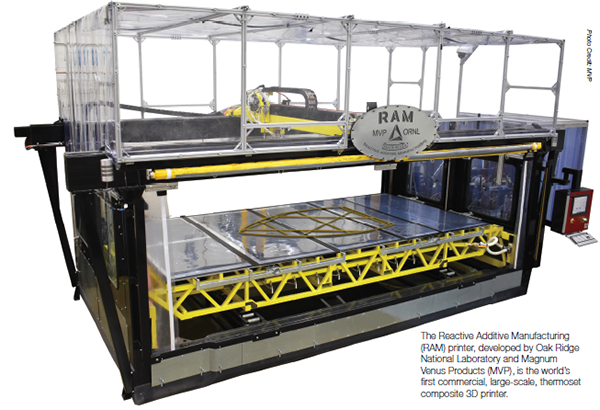

Thermoset composite materials could be used to overcome some of the problems in such applications, but until recently there’s been no large-scale additive manufacturing process for thermosets. Now there is. Over the last few years, Oak Ridge National Laboratory (ORNL) and Magnum Venus Products (MVP) co-developed the world’s first commercial, thermoset Reactive Additive Manufacturing (RAM) machine and partnered with Polynt Composites USA to develop a novel print material. The system can print parts as large as 8 x 16 x 3.5 feet.

Each of the partners brought experience and expertise to the RAM creation process. ORNL helped develop the Big Area Additive Manufacturing system (BAAM) for printing 3D thermoplastic parts. MVP has decades of experience in pumping solutions for composite manufacturing and in large-scale, automated production systems. Polymer chemistry supplier Polynt has developed coatings for 3D thermoplastic parts.

While their knowledge of 3D thermoplastic printing was helpful, the team had to develop a very different printing process for RAM. In thermoplastic 3D printing, heat is the key. The equipment melts a polymer material (continuous filament or pellets) so that it can flow through a nozzle that deposits it, layer by layer, on a heated printer table.

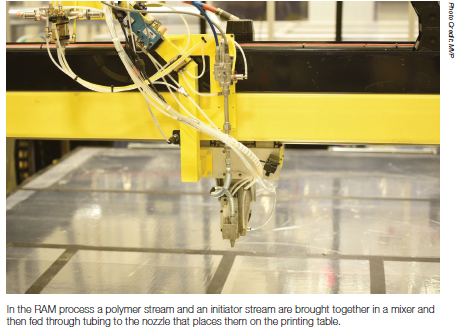

RAM, however, is an ambient temperature system that uses pumpable liquids to manufacture thermoset parts. Its raw materials include a formulated polymer with reinforcing fibers (the A side) and a peroxide initiator (the B side). The two sides are brought together in a mixer, beginning an exothermic reaction that continues as the mixture, which has the consistency of toothpaste, is deposited through a nozzle onto the printer table. A gantry moves the nozzle around the printer table, which lowers to accommodate the part’s growing height as the layers are added.

Polynt formulated PRD 1520 specifically for the RAM process, says Rick Pauer, applications specialist, Polynt Composites USA. The polymer/initiator mixture had to be void free, curable and able to set up rapidly so it didn’t slump or liquefy during the printing process. It had to maintain its viscous properties during the exothermic reaction and deliver all the mechanical properties that potential customers would want.

The team has printed several test parts on the RAM machine with the PRD 1520 formulation over the last year. ORNL and MVP have also been developing another thermoset printing process for RAM. It combines liquids from an epoxy resin line and a hardener line, but doesn’t include fiber, so it isn’t a composite material. Unlike most products produced using PRD 1520, these epoxy-printed parts require post-printing curing in an oven.

Taming the Heat

Some researchers have already employed additive manufacturing to produce small-to-medium-sized thermoset parts. But the processes and materials they used could not be directly adapted to large-scale production.

“When you’re dealing with exotherms, when these chemical reactions occur they generate heat,” says Christopher Hershey, postdoctoral polymer engineer at ORNL. The amount of heat generated depends on how much mass is reacting because polymers in general don’t cool down very efficiently; they store their heat and maintain it for quite a while.

On a small-scale system with a small bead (the connected drops of material along the print line), there’s not a lot of heat produced by the exothermic reaction, so it doesn’t affect the printed part. With a large-scale system, however, there’s more heat generated through the reaction and it accumulates in the printed mass. That affects the material that’s already been deposited and the material that’s being added.

“When the temperature increases, the rigidity and the viscosity [of the material] decreases, and we found it was decreasing below a value that could support the bead that was being deposited,” Hershey says. “On the first layer, you’re printing on a nice, cool, aluminum bed, but as you get higher and higher, you are depositing [the material] onto a much warmer substrate. You get to the point where this accelerates the reaction, which causes the exotherm to rise and the rigidity to fall,” he adds.

In other words, as the temperatures rise, the material that’s being laid down begins to look as if it’s melting off the part. This was one of the challenges that Polynt faced when developing PRD 1520 for RAM. The company was able to formulate the polymer to reduce the effect of exotherm on the viscosity of the process materials.

Forming Strong Bonds

3D-printed thermoset composite parts provide many of the same benefits as traditionally manufactured thermoset composites, including chemical resistance, creep resistance and heat resistance.

“With thermosets, you can have a wide range of formulations because there are many different types of chemistries available and there are many different types of additives that can be used,” says Hershey. “You can create functionality and increased strength for your final part.”

Strength and other mechanical properties are fairly uniform throughout a thermoset-printed part because the chemical reaction between the polymer and the initiator enable the formation of bonds between all the layers of the part. The coefficient of thermal expansion (COE) values, which measure how the size of an object changes with a change in temperature, also remain fairly consistent throughout the part because of this strong chemical bond.

Large thermoplastic-printed parts, by contrast, can’t offer that strength throughout the part, even when they’re reinforced with carbon fiber. During the 3D printing process, the carbon fibers align in the direction of flow out of the extruder, providing high strength in the X and Y directions but little in the Z direction. There’s no chemical reaction that bonds the layers; the strength of this bond depends on how well each layer melts or fuses to the previous layer.

This alignment of the carbon fibers in the printed thermoplastic composite part also produces coefficient of thermal expansion (CTE) values that are significantly different between the X and Y directions and the Z direction. This is one reason why thermoplastics aren’t as well suited for high-temperature applications.

Finer Resolution

With thermoset AM, parts can be manufactured precisely and with less material. The nozzles used for thermoplastic 3D printing generally have opening diameters between ½-inch and 3 inches. That’s because the material has to be deposited as quickly as possible so that it won’t cool down too soon. “They have to come back to the previously deposited layer in a certain amount of time, because if they don’t the bottom has cooled too much and the top layer won’t stick to it,” says Mike Kastura, senior product manager at MVP.

With thermosets that’s not a concern because the bond is formed by a chemical reaction. Since there’s no need to make the beads large or to hurry the printing process to ensure the material retains heat, the nozzle size can be smaller.

“Most of the prints we are doing are with a 0.2-inch-diameter nozzle, so we are printing on a much finer resolution,” Kastura says. The part can be printed more precisely, so there’s less overprinting and less milling required to produce its final shape.

Sparse infill printing of thermoset AM parts also reduces material use. “We save time and money by essentially printing a honeycomb structure and not a solid print until we get near the surface that will likely be required to be milled,” explains Pauer.

The development team hopes the RAM equipment’s fine resolution capability will enable it to produce final parts rather than tooling to make a part. A 3D-printed replacement part could be ready in a few days rather than the weeks it takes to make a part from a 3D-printed tool.

Saving Energy

Since the U.S. Department of Energy sponsors ORNL’s research, the energy efficiency of additive manufacturing is a big concern. Thermoset 3D printing has an energy advantage over thermoplastic AM.

There are several energy-consuming steps in thermoplastic 3D printing. One is the conversion of the commonly used material, acrylonitrile butadiene styrene (ABS), into a polymer. Another is the re-melting of the ABS in a compounder to include additives like carbon fiber. The ABS, now in pellet or chopped form, is melted a third time for deposition during the print process. In addition, the printing table is typically heated during the thermoplastic printing process to prevent the parts from cooling too fast.

Thermosets, by contrast, require heat to make the original polymer, but beyond that the only added energy is what’s required to pump and mix the PRD 1520 as it’s processed through the RAM equipment.

The Electric Power Research Institute (EPRI) found that the thermoset additive manufacturing process is about 500% more energy efficient than the thermoplastic process, Hershey says.

Intriguing Possibilities

The ability to control the exothermic reaction in the RAM process provides opportunities to vary the characteristics of a part.

“With thermoplastics, once you lay the bead down that’s the hottest it’s going to be. It starts to cool so you can’t print through it,” says Kastura. “That’s not true with thermosets. You can literally cross through that previously laid bead on the same plane, so you can have different geometries, different print patterns.”

In addition, the RAM machine can be equipped with a robotic claw that can insert objects into a part as its being printed. “The claw could grab pipes for heating or cooling channels and drop them precisely into your print because it’s all part of the machine code,” says Kastura.

The claw could also precisely install different types of sensors inside a tool as it’s being manufactured. Those sensors could relay data to help predict the part’s end of life or to validate a tool’s effectiveness during the process by providing metrics at certain times. Embedded sensors could be used to monitor temperature within a tool to ensure that it’s at the proper temperature while it’s being used.

One other unique feature of RAM is its patent-pending removable printing table, which will enable a shop to index the table rather than the part, then easily move the printed part to its next location, such as milling or routing. Then, by inserting another table, the shop can continue to make the best use of its high-demand AM equipment.

Testing It Out

Thermoset additive manufacturing is attracting attention from government and commercial customers, including the military, automotive/transportation, wind/aerospace, tub and shower manufacturers and job shops. “Many of them have looked at thermoplastics 3D printing, and they know some of the limitations. There’s a strong case that can be made that thermosets can solve a lot of those issues,” says Kastura.

The RAM team continues to do more printing and testing to help ensure the new technology’s widespread acceptance. One part, printed for Design Concepts/Marine Concepts (DCMC), is a direct mold that would be used to create lightweight carbon fiber mold insets for a 60-plus foot deck liner.

“The part, measuring 10 x 4 x 2 feet and weighing 1,000 pounds, was large enough that it pushed the envelope for them as far as size, and it also aligned with one of our internal R&D projects, which was to develop an alternative to heavyweight standard mold insets,” says Ross Kennedy, director of business development at DCMC.

Company representatives watched the part being printed on the RAM equipment and shipped it back to their facility to mill. “It was a learning experience for everybody,” says Kennedy. “We got to understand better ways to index these oversized, near-net shape prints and provided feedback.” DCMC also tested the vacuum stability and surface finish on the printed molds.

Milling the printed thermoset composite was similar to milling a very high-density urethane tooling board. “The benefit that I see with the 3D print is that you can have a sparse interior, which uses a lot less material than a giant block of tooling board,” says Kennedy. In addition to lower material use and weight, the near-net printing discipline directly translates to less material having to be milled away.

Research on RAM has been slowed by coronavirus-related shutdowns, but when work can resume the RAM team will print another part for DCMC to see if the changes that they’ve made to the machine and the process have improved the printed product.

In the long term, Kennedy says there are three criteria that RAM-printed parts will have to meet for the equipment to gain a place in large tooling shops. One is the surface quality – the density and hardness – of the printed part. It will also have to meet glass transition temperature requirements and offer the right coefficient of thermal expansion properties. He expects that thermoset 3D printers like RAM will be able to meet those criteria very soon.

“We certainly feel that at some point this will become an everyday item in the larger tooling shops around the world,” he adds.

Ongoing Improvements

The RAM team will resume its research once work schedules at ORNL permit. ORNL and MVP have recently signed a second creative research and development agreement (CRADA), and Polynt is waiting on approval of its second CRADA with ORNL.

One problem the team plans to address is process speed, which is currently much slower than thermoplastic AM. To increase the rate of printing, the team will have to find a way to ensure a steady stream of the materials, which are currently available only in relatively small barrels that empty quickly. In addition, the hoses, which are about 30 feet long to reach all sides of the printing table, must have a diameter large enough to handle heavier flows of the viscous material used in the process.

The team may also explore the feasibility of adding another stream to the material being deposited during the RAM printing process, such as a second resin formulation that could add a functional coating to the surface of a printed part. In addition, it will continue to refine the thermoset printing process, work toward getting better resolution for near-net shapes and build case studies with industry partners to prove out the technology.

“There will no doubt be new challenges we have to overcome, just like we did in thermoplastics, but you don’t have the limitations in thermosets that you have in thermoplastics,” says Kastura. “We will be experiencing some of the excitement that we felt when we first started thinking that 3D printing could take over the world.”

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.