Putting Customers First

There is a lot of lip service paid to the importance of customer service. But leaders in the composites industry do more than talk the talk. They adopt a customer-centric business model, making clients the focal point of everything they do. This approach not only benefits the customer, but it sets the companies apart, too.

“It’s so important for companies to differentiate themselves, whether they are building a boat or airplane components,” says Megan Multanen, co-CEO of Bestbath. “There is somebody else in the industry doing what you do, and they may have more buying power or more brand name recognition than you. But you can differentiate yourself by focusing on the customer and really taking care of them.”

Any company can become customer-centric, no matter their size or specialty, as is shown in this article by insight shared by three diverse companies: a manufacturer of pultruded products that’s part of a larger group of companies, a family-owned manufacturer of bathing products and a leading distributor of raw materials and processing supplies.

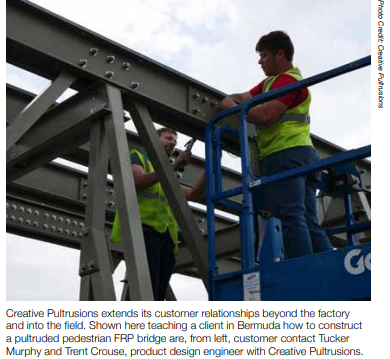

Creative Pultrusions: Solving Problems

“To have a successful business, you need to put customers first. That’s pretty obvious,” says Dustin Troutman, director of marketing and product development for Creative Pultrusions Inc., one of five companies comprising the Creative Composites Group. “But to continue to grow organically, what we do best is partner with our customers and help them solve problems.”

The first step toward a partnership is deciding if a prospective customer is a good match for Creative Pultrusions. “If it’s a simple pultrusion all about price and not performance, then we are not a fit,” says Troutman. “We are a fit when we can use our production and product development engineering solutions to solve problems on a higher end scale.” The manufacturer gathers a wealth of information about potential projects, including the application, performance expectations, budget information and price barriers. If the project is well-suited to Creative Pultrusions’ capabilities and business model, then Troutman says, “We embrace the project 100% and work hand-in-hand with our customer to come up with a solution.”

Because composite applications are complex, the company collaborates with clients on technical components of their projects. Creative Pultrusions has three engineers in its structural group to help clients develop specifications for their custom applications. The company has a metrology lab where it can perform most of the standard material characterization tests necessary to develop mechanical properties for GFRP materials. The company also maintains three flexural test units for full-scale component testing and first article validation.

“FRP is a unique material, and you have to understand exactly how you’re applying it,” says Troutman. “We develop characteristic design strengths for our customers and establish the relative mechanical and physical properties so they know exactly how their part will perform.” For instance, Creative Pultrusions designed a pultruded tube for one client, who also asked the company to develop accompanying design and quality standards related to their internal and external requirements. Creative performed three production runs, taking tubes off the production line and testing them to failure, then performing a statistical analysis to help the client draft its structural and quality requirements for the finished product. These requirements then become Creative’s production requirements.

However, Creative Pultrusions isn’t just concerned with product details; it prioritizes customers’ needs all along the sales cycle. “One way we record the voice of the customer – and make sure everybody within our company understands the voice of the customer – is by documenting it in our advanced quality planning (AQP) system,” says Troutman. “All relative personnel has access to the AQP and can pull it up whenever they have a question.”

At the beginning of each project, company representatives meet with the client and document every pertinent detail in the AQP system. In addition to design and manufacturing requirements, the system includes agreed-upon steps the company and customer will take if mishaps happen during delivery, a product sometimes gets scuffed or it needs to be repaired. “We try to prepare for all this upfront because it’s not a matter of if, but when something is going to get damaged during transit. We know upfront, based on the degree of damage, if the product will get discarded or repaired and how it will get repaired. ” says Troutman.

Another testament to the company’s commitment to customers is its tooling policy. “Whenever a client buys a pultrusion die from us, they invest in tooling for life,” says Troutman. “If the die wears out, we build a new one on our dime.”

Troutman cites one defining characteristic in Creative Pultrusions’ quest to put customers first – transparency. “Be transparent with both the positive and negative attributes of composites and how they behave,” he says. “Engineers want to design based on the positive attributes, but more importantly they want to know what can go wrong and how to overcome it during the design phase.”

The same principle holds true when a problem occurs. “People will respect you more if you pick up the phone and say, ‘We have a problem.’ When you do, you can show your customer how good you are at solving that problem and making things right,” says Troutman.

Bestbath: Listening Closely

Multanen says Bestbath’s customers are their No. 1 resource. “We think we know how to solve our customers’ issues, but the reality is it’s the general contractors and architects who are truly dealing with funky drain locations, interesting plumbing or local codes,” she says. “They tell us about their unique needs, then we can provide solutions for those issues.”

The job of listening to customers – truly listening – begins with the sales force. Bestbath has 27 employees in its sales department, 13 of whom are outside sales representatives. As employees of the company, rather than contracted salespeople, they have a vested interest in building relationships with customers. “Our sales reps connect with customers in a powerful way, and they are connected back to the company at large,” says Multanen. “They have the time, the directive and the desire to ask their customers important questions. And they have the time, directive and desire to pass that information back to us.”

Bestbath has developed a built-to-order Bestbuilt™ manufacturing process to ensure that customers’ requirements are met on every order. It begins with the client working side-by-side with sales reps on product specifications, then goes through design and production, with a series of quality assurance checkpoints along the way. Created with the customer in mind, the process helps reduce the chance of mistakes, accommodates changes during design, allows for shorter lead times and provides clients real-time information on when orders are being built and will be shipped.

Another example of Bestbath’s dedication to customers is its commitment to sharing knowledge. “We have worked hard during our 50-plus years in business to truly be experts in the shower industry,” says Multanen. “We do a lot of webinars and white papers that provide useful, important content for potential customers.”

Photo Credit: Bestbath

Webinars cover topics ranging from design trends in single family housing to building code compliance. The white papers present specific projects with architects, builders, general contractors and plumbers. For example, one white paper discusses a new trench drain gate Bestbath developed for showers in Sunrise Senior Living facilities across the U.S. based on extensive conversations with the client. “Some of the things they wanted re-tooled and some of the design elements they requested were not special to them,” says Multanen. “These are things that other people in senior housing are concerned about.” By sharing project details in the white paper, Bestbath can help others seeking similar solutions.

Naturally, the branded webinars and white papers help promote Bestbath. But it’s not solely about generating revenue. “Sharing information doesn’t always lead to closing a sale,” says Multanen. “We are a resource for people, and they may go elsewhere.” And she’s OK with that.

When Multanen and other leaders at Bestbath discuss how to stand out from competitors, it’s not all about the products they make. They reflect on what kind of organization the company wants to be. At the heart of those discussions are people – customers and employees.

“I could sit there and talk about why my shower with barrier coat is so much better than a shower that doesn’t use barrier coat,” says Multanen. “But one of the things that resonates with customers who are considering using our products is the way we truly take care of employees. We commit to regular schedules, a safe environment, and a living wage and benefits. That helps tell your story and helps customers understand why they might want to commit to a longer relationship with you.”

Composites One: Sharing Knowledge

Leon Garoufalis, president and COO of Composites One LLC, says it may sound cliché, but without the customer there is no company. “As a distributor, we don’t manufacture any products. It’s not like we can bring our own products to market with our own developed innovations,” he says. “For us, it’s all about serving the customers and creating value in different ways.”

One of the ways that Composites One serves its clients is by providing training in processes, products and applications. The company works with partner suppliers, as well as organizations such as ACMA and IACMI – The Composites Institute, to host workshops and teach the principles of closed molding. It also presents webinars. In 2020, webinar topics included tooling, vacuum infusion processing for aerospace and wind energy applications.

In 2008, Composites One formed the Closed Mold Alliance to provide training and resources related to complete closed mold solutions. Working alongside alliance partners Magnum Venus Products and RTM North Technologies, the company hosts hands-on demonstrations of vacuum infusion, light resin transfer molding and other advanced processes. During CAMX 2020, the Closed Mold Alliance held seven virtual demonstrations under the tagline “Knowledge is Power.”

Composites One also collaborates one-on-one with clients. “We work with customers and, in many cases, conduct turnkey conversions from open molding to closed molding environments to greatly improve product quality and manufacturing efficiencies,” says Garoufalis. The company helps customers assess their products, select the right closed mold process for those products, manufacture molds and train employees. It also offers technical assistance for initial trials of new manufacturing methods.

Providing ongoing technical support is paramount to Composites One. Most of its salespeople have years of experience in the composites industry, many on the manufacturing side. “They are not just out there to sell products,” says Garoufalis. “They are there to solve customers’ problems and help them work through issues to become more efficient and effective.”

Of course, the company hopes that serving as a resource for customers will spur them to do business with Composites One rather than its competitors. “If we’re doing the right things for the right reasons for our customers, over time we will benefit as well,” says Garoufalis.

Recognizing that “Knowledge is Power,” Composites One is also committed to helping educate the next generation of composites employees. For example, it sponsors the composite materials technology program at Davis Technical College in Utah. The 900-hour program – designed for industry, by industry – introduces students to basic composite materials, techniques and procedures, then progresses through advanced composite skills. The college boasts a 94% placement rate for students in the composite materials program, who graduate with both a local industry-driven certificate and ACMA’s Certified Composites Technician (CCT) designation.

“We are helping train people so they can go to work for our customers,” says Garoufalis. Assisting customers with their workforce needs is critical in an industry that faces challenges in finding, training, growing and retaining employees. Composites One is currently working with IACMI and Davis Technical College to replicate the program in other composite hubs around the country.

While Garoufalis and his leadership team at Composites One fully support a customer-centric business model, that’s not enough. For customers to genuinely be the focal point of a company, you need employee buy-in, says Garoufalis. “If employees don’t understand how critically important it is to serve customers, then it doesn’t matter how much we speak about it,” he says. “Team members have to internalize the concept of serving customers.”

When everyone in a company puts the customer first, then good things happen. “In our organization, it’s all about serving the customer and creating value,” says Garoufalis. “If our customers are successful, then we are successful.” And if composites companies are successful, then the entire industry will thrive, too.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.