Restructuring Homebuilding with 3D Printing

Mighty Buildings, winner of CAMX’s 2020 Unsurpassed Innovation Award, is prepared to shake up the housing construction industry in a big way. Its factory-built homes aren’t made of wood, concrete or other traditional materials, but are 3D-printed using polymeric, UV-cured materials. This new production method significantly reduces the time and labor required to produce a home, cuts construction waste to near zero, produces an energy-efficient structure and significantly lowers the cost of home ownership, according to the company.

“Construction is the last industry that hasn’t really been disrupted by embracing technology. We're still building using more or less the same technology we did 120 years ago,” says Sam Ruben, Mighty Buildings’ chief sustainability officer and one of the company’s four co-founders. “So there's a real opportunity to help solve some big problems, like the housing affordability crisis and housing scarcity, through the embrace of new technologies and new ways of doing things.”

After starting Mighty Buildings in Redwood City, Calif., in 2017, the founders spent three years refining the additive manufacturing and robotic technology, the printing material formulations and the system’s software. In late 2019, the company moved to a larger production facility in Oakland, Calif. The company officially launched out of stealth in August 2020, having already delivered the first units of their initial product line of pre-fabricated accessory dwelling units (ADUs).

“We really wanted to make sure that we had everything locked in, including our certification roadmap,” Ruben says. “With buildings, we're dealing with a regulatory structure that's literally written in blood. So it's really important that we're doing everything we can to ensure full compliance with the building code and that we're able to demonstrate the safety of what we're doing.” The founders located the plant in California because of the state’s stringent building codes. “By starting here in California, it makes it easy to move into other states and other countries without too much additional testing,” Ruben says.

Mighty Buildings worked with the safety certification company UL to determine the methods and samples required to test and certify the tensile strength, compressive strength, thermal cycling, fire rating and other characteristics of the 3D-printed buildings. Their efforts resulted in a new UL 3410 standard for 3D printing in construction, which will be included in the International Code Council’s 2021 International Residential Code (IRC). Mighty Buildings was the first to achieve this certification and is also one of the companies currently assisting the standards organization ASTM with development of similar international standards for construction 3D printing.

A 79,000-square-foot former coffee warehouse is home to Mighty Buildings’ automated production line, which includes a large-scale additive manufacturing printer and one automated robotic cell. It takes 24 hours or less to print and put together the composite components required to build a 350-square-foot ADU. The process requires 95% fewer labor hours than traditional building and generates just one-tenth of the waste, according to Mighty Buildings’ co-founder and COO Alexey Dubov.

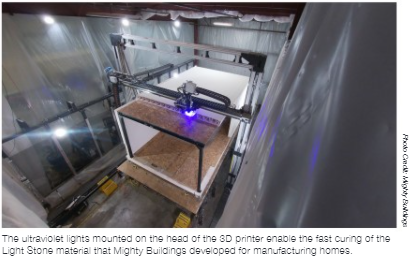

The 3D printing system includes a basic gantry, a moving frame and a unique, rotatable printing head mounted with ultraviolet (UV) modules. For the construction material, Mighty Buildings developed a proprietary, pre-mixed material of mineral and resin called Light Stone. This thermoset composite is in the same class of materials as Corian’s solid surface materials but has a Class A flame spread rating instead of Class B.

“We can turn the material into a gel that allows us to extrude it into pretty much any shape,” Ruben explains. “Because of the UV curing that we’ve introduced, it cures quickly enough that it can support its own weight, but not so quickly that we don't get full cohesion between the layers.” Before printing a structure, Mighty Buildings uses simulation software from MSC Software to identify potential production bottlenecks or design issues.

To date, Mighty Buildings has focused on printing the composite components of its first modular product line, Mighty Mods. The available buildings include one 350-square-foot model and two 700-square-foot buildings; all come equipped with a full bathroom and a kitchen area and can be customized. The Mighty Mods can be used for a variety of purposes, including housing for extended family, space for a home office or an income-generating rental property. Mighty Buildings prints the equipped Mighty Mods in the factory, trucks them to the building site and then lifts them into place using cranes. (You can take a virtual tour at tour.mightybuildings.com.)

The buildings’ walls, supported by a steel frame, consist of two panels, between eight and 14 millimeters thick, which are separated by a six-inch cavity filled with a high R-value foam insulation. Exterior walls currently feature traditional building cladding, but Mighty Buildings expects its Light Stone material will achieve a minimum one-hour fire rating, which means it could serve as the ADU’s exterior walls.

The company plans to introduce a fiber-reinforced material sometime in 2021; the addition of the fibers into the printed material will be automated. “With the new fiber reinforcement, it's going to allow us to eliminate any need for steel because the performance of the reinforced material is actually better than reinforced concrete walls, with four times less weight and four times more insulation,” says Ruben.

This stronger material will enable Mighty Buildings to introduce a 3D-printed panel system that will provide greater flexibility in home design, including the construction of additional stories to the basic buildings. The company has developed a plug-in for Autodesk® Revit building information modeling software that allows home designers to create custom floor plans. Mighty Buildings can then convert those plans into panels, 3D print them and ship them to a building site for assembly.

Mighty Buildings’ simulation capabilities should drastically reduce the cost of introducing new building designs because they allow for multiple virtual builds before the structures are printed. “We identify a lot of potential issues up front, which also means that we're going to be able to speed that new product introduction time by as much as five times,” says Ruben. The technology can be used by developers that cater to every market, including high-end, middle market and affordable housing.

3D printing is a more sustainable way to build homes, Ruben says. Traditional building generates about two kilograms of waste per square foot, while the 3D process generates just 0.02 kilograms, which can be recycled into new material as filler. In addition, 3D-printing homes could help solve the building industry’s chronic worker shortage. Although Mighty Buildings’ technology reduces the number of skilled workers required to produce a home, it also creates technology-related jobs that are less physically challenging.

As of November 2020, the company had installed four of its ADU structures in California, had three completed on its factory floor awaiting installation permits and another 14 in process. The company plans to expand its factory to six production lines by the end of 2021 and to open factories in other locations starting around 2022.

“We’re looking at being able to set up a factory for less than $10 million in three to six months, and out of that to be able to generate 600 to 1,000 units a year, depending on the design,” Ruben says. In addition, Mighty Buildings has signed agreements to work with companies throughout the world; one U.S. developer has expressed interest in building 10,000 units a year once the technology can produce them at that scale.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.