Biocomposites in Wind Energy

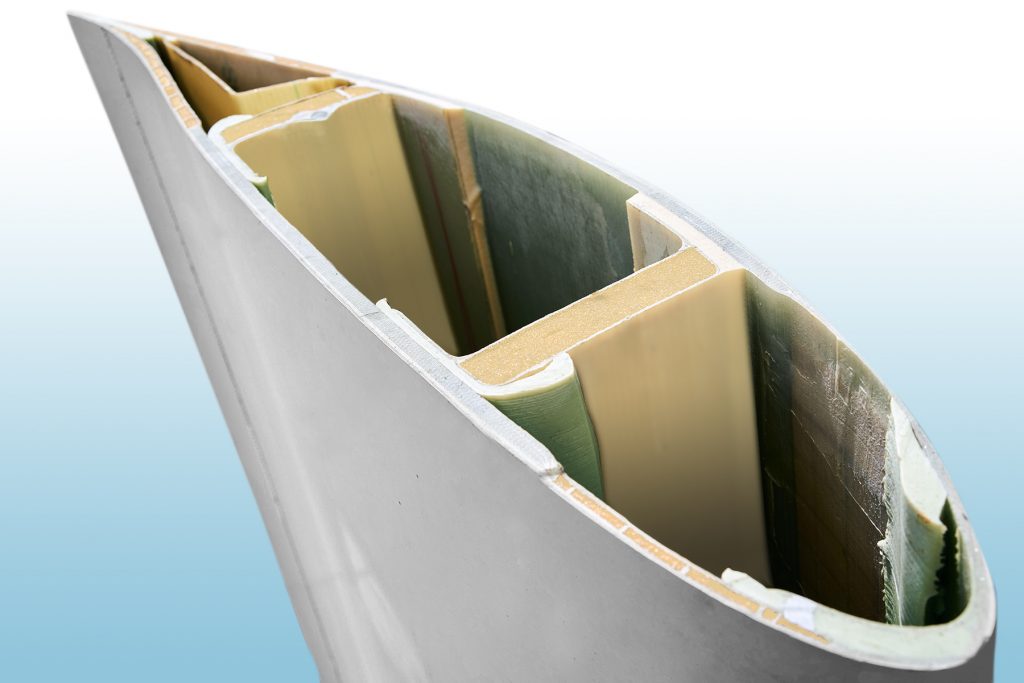

The world’s increasing reliance on wind energy has spurred demand for wind turbines and the giant blades that power them. But meeting those market needs has been difficult due to the shortage and skyrocketing cost of balsa, the strong, lightweight wood that is sandwiched between GFRP to create wind blades. At least one blade manufacturer has been using polyethylene terephthalate (PET) and polyvinyl chloride foam (PVC) foams in blade tips, but it still requires balsa to provide shear modulus for the root section of the blade. Within the next two years, Canada-based INCA Renewtech will offer an alternative – a sustainable biocomposite that could replace balsa at any location in the blade. INCA BioBalsa™, manufactured from hemp fibers, has a density comparable to balsa (10 pounds per cubic foot) and an even better compressive strength than the wood due to its random fiber placement, according to the company. INCA says BioBalsa is cost competitive and more sustainable than balsa and foam, and unlike balsa, can be engineered to provide both moisture and fire resistance. The hemp for BioBalsa comes from the Canadian prairies, where farmers have been growing the plant as a protein source for two decades. “But the tall stalks of the hemp plant, which contain some of the strongest fibers on earth, were underutilized, used as horse bedding and for soil remediation,” says David Saltman, INCA Renewtech’s chairman and CEO. “We realized that if we could process and refine the hemp ourselves to make textile grade materials, which is roughly 99% pure fiber, we could build our own composites out of that material. We could utilize what had essentially been a waste stream and get a much higher value out of a low-cost raw material.” INCA Renewtech has developed applications for every part of the hemp plant. BioBalsa is made with short fibers from the hurd – the woody inner part of the stalk – which replace glass fiber as the reinforcement material. The company is in full-scale manufacturing line trials for composite prepregs for Toyota. It is also trialing a plywood replacement called BioPanels™ made from hemp’s long fibers for Genesis Products. Sustainable manufacturing is key to INCA Renewtech’s business model, and that approach is demonstrated in the manufacture of BioBalsa. A lifecycle assessment from GreenStep Solutions found that one cubic meter of BioBalsa sequesters 260 kg of carbon dioxide. “You not only have that sequestration during the growing period, but if you're going to put the product into a wind turbine blade – and that has a life of 20 or more years – that means that carbon continues to be sequestered,” says Camille Saltman, chief marketing and sales officer, INCA Renewtech. The company has also developed technologies that will enable deconstruction and material recycling of decommissioned blades. Camille Saltman says BioBalsa production generates 107% less greenhouse gas emissions and reduces waste generation by 93% compared to the cutting and milling of balsa wood. It generates 164% less carbon emissions than PET and has 99.56% less waste production and 93% less water consumption than foam production. Gurit, an advanced composites supplier that works with the wind energy industry, was attracted to INCA Renewtech’s BioBalsa work in part because of the company’s emphasis on sustainability. “The BioBalsa project fits nicely with Gurit’s ambitions as a sustainability leader,” says Thomas Nauer, the company’s head of marketing, communications and sustainability. “The wind turbine industry is aiming at zero-waste, recyclable turbine structures and is looking for ways to further reduce its greenhouse gas footprint. Therefore, a material that is both bio-based and made from recycled components is clearly a benefit and provides an answer to both sustainability and technology trends.” Over the past nine months, INCA Renewtech has been working to engineer BioBalsa to Gurit’s specifications. “We have the ability to formulate the product to meet very specific market demands,” explains Garry Balthes, chief technology officer. “We sent Gurit an initial product that we felt closely resembles or replicates balsa, and they tested it and provided data back on what direction we needed to go. That has allowed us to focus in on making adjustments to the formulation in order to meet the exact demands for whatever part of the wind blade the BioBalsa is going to be used for.” Nauer notes that the specific properties of BioBalsa, including its density and the resin uptake of the material, will define the parts of a wind blade where it will be most suitable and competitive with other materials. BioBalsa is resin agnostic, but the percentage of resin in the material remains relatively low because of the properties found in natural fibers. “Trees and plants in general have natural lignans that bind them together, so we can actually capture and utilize that lignan as a binder,” says Balthes. “We don't go over 30% resin, whether it's liquid resins, dry resins, a photoresist base, or a hybrid base. We're probably going to be able to drop that percentage down even more.” INCA Renewtech will mass produce BioBalsa at a new 164.000-square-foot hemp processing and composite manufacturing facility in Alberta, Canada, and its other hemp-based composites at a new 235,000-square-foot manufacturing facility in Elkhart County, Ind. IPCO AB, which has worked on other projects with INCA Renewtech, will design and manufacture the BioBalsa production equipment. Michael Tobiasz, IPCO’s regional product specialist and business development manager for composites in North America, says it will feature a Teflon™ double belt press that will consolidate the materials, heat them and exert the equalized surface pressure necessary for the desired calibration, thickness and densities of the material, and then cool it. The IPCO equipment will be a continuous process machine, capable of producing the long lengths of BioBalsa material that the wind blade industry might require. The manufacturing line is being designed for maximum production flexibility. “The line is designed right now to run 100 pounds of BioBalsa per minute. That’s a line speed of 10 meters a minute, at 40 inches wide, a half-inch thick and a 10.5-pound density,” says Balthes. “But we can very quickly adjust the layering so that we can make it a 15- or 20-pound density.” Large-scale production of BioBalsa for wind blades should begin at the factory in early 2024. In the meantime, INCA Renewtech and Gurit will put prototype BioBalsa blades through the independent laboratory testing required to gain widespread market acceptance for the new biocomposite. David Saltman is optimistic about the future but realizes hurdles remain. “We know with Gurit, we have to be performance competitive, we have to be price competitive, and we have to be manufacturing at volume,” he says. He acknowledges that achieving all that is a lot to accomplish in less than two years. “The real challenge is that we have to go from zero to 60 in four seconds,” he says. If their efforts are successful, BioBalsa could become an integral part of the wind energy industry before too long. Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net. Prepare for a Sustainable Future ACMA is committed to sustainability. It has launched a Climate Impact Project to provide essential tools, resources and education to help composites manufacturers assess climate impacts associated with production of their products and raw materials, as well as provide information requested by customers. For more information, visit acmanet.org/acmas-climate-impact-project. BioBalsa, a composite made with the fibers found in hemp hurd, has the necessary properties to replace the natural balsa wood that provides internal support for giant wind blades.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.