Opportunities in Thermoplastic Pultrusion

Pultrusion offers many advantages for companies that want to produce consistent, high-strength and dimensionally accurate parts through a highly automated system. Thermoset matrices have been the material of choice for years, but researchers now hope to expand the use of thermoplastics in pultrusion as well.

In May 2023, at the North American Pultrusion Conference hosted by ACMA in collaboration with the European Pultrusion Technology Association, researchers shared the results of thermoplastic pultrusion projects and opportunities they present in the composites marketplace.

Nylon 6-Based Profiles

At the Fraunhofer Institute for Chemical Technology ICT in Germany, Michael Wilhelm and his co-researchers have developed a processing method for a reactive thermoplastic matrix system for pultrusion using nylon 6 (polycaprolactam). Their research focused on the robust processing and functionalization of the pultruded parts and ecological and economic aspects of the thermoplastic pultrusion process.

There are several reasons for increased interest in thermoplastic pultrusion, Wilhelm says. When pultrusion was introduced in the 1950s, composites with high fiber fills could only be impregnated with low viscosity thermoset resin systems, such as vinyl esters, polyesters and epoxies. New materials have opened the possibility of using reactive thermoplastic resins like nylon 6 or PMMA (polymethyl methacrylate), which are in the same price range as thermoset resins.

Recycling of composite parts is also important today, especially in Europe, where manufacturers must increasingly be able to prove the recyclability of their materials to OEMs. Components produced using reactive in situ thermoplastic pultrusion are easy to recycle.

“You also have the possibility of functionalization with thermoplastic pultrusion,” Wilhelm says. “With thermoset profiles, you don’t have the ability to thermoform or overmold them with a strong material connection. With thermoplastics, you can just heat up a profile, place it in an injection molding die or a compression molding die, and co-mold or overmold it with shorter fiber-reinforced polymers.” Providing this local reinforcement for the composite part reduces the need for the time-consuming and expensive process of cutting, placing and consolidating layers of reinforcing tapes.

To produce these thermoplastic pultrusions, Wilhelm’s team used a reactive process in which impregnation of the pre-heated fibers and polymerization of the matrix takes place in a heated die block.

“The big benefits of this process are the extremely low viscosity of the monomer and the adjustability of the reactivity by changing the amount of activator and catalyst, so you can make the resin’s polymerization quite fast,” says Wilhelm. This results in a composite with a very high fiber volume content and better adherence between the fibers and the matrix.

The equipment for producing pultruded thermoplastic and thermoset profiles is similar, however the thermoplastic process also requires a pre-heating and drying unit and a metering and mixing machine.

The team faced some challenges in developing this process. Since caprolactam – the monomer of nylon 6 – can be negatively affected by moisture, they used special matrix formulations and handling methods to avoid those problems. They also dealt with limited availability of the special sizing required to get a good adhesion of the thermoplastic matrix to the fiber.

The researchers compared the properties of thermoplastic profiles made with nylon 6 and Elium® resin from Arkema with thermoset profiles made with epoxy and vinyl ester.

“We saw that the pultrusions based on reactive thermoplastics were definitely comparable to thermosets and in some cases had slightly higher properties,” says Wilhelm. “But the properties are always dependent on the use case, so it’s important to look at the use case and decide if a thermoplastic or a thermoset is more suitable to use. We don’t want to replace all thermoset profiles, but whenever the benefits of thermoplastics can be used why not use them?”

Recyclability of the thermoplastic profiles was part of the researchers’ work. “We did a study to find out which recycling route and formulation would lead to good mechanical properties compared to virgin materials,” says Wilhelm.

With mechanical recycling via shredding of the profiles and the use of injection molding, the team found that a part made with recycled materials achieved nearly the same properties as one made with virgin materials. The properties of the part did depend on the amount of recycled material included in it. The team is currently studying the properties of nylon 6 that is removed from a part using chemical recycling.

The team used digitized sensors during their research to collect data about the interaction of materials in various processes and to look at properties and special material behavior that could never be seen before. Wilhelm says this digitization process has drawn the interest of industry, which needs this type of data to provide information about the CO2 produced and the energy used during manufacturing. Manufacturers could also use the collected data to improve the quality of their products and the efficiency of their processes.

Wilhem says their research has shown that a good business case can be made for industrial use of thermoplastic profiles. They are currently working on research projects in construction (rebar), transportation (battery enclosures) and the wind industry (spar caps).

“We have already started with the first customers on the process to series production, and I hope we can realize the first automotive part – which has in-situ pultruded profiles – by the end of this year,” Wilhelm adds. He hopes this proof of concept case leads to the scaling up of mass production for hundreds of thousands of parts per year.

GFRTP Pultruded Rebar

FRP rebar made with thermoset matrices offers many advantages in concrete bridge and highway construction, including its strength, light weight and corrosion resistance. But it has some disadvantages. Unlike steel rebar, it can’t be bent into different shapes at the construction site and is not easily recycled.

Pultruded thermoplastic (GFRTP) rebar could be the solution. After their initial fabrication, these reinforcement bars could be sent to the jobsite where they could be reheated and formed into hooks, stirrups or other special configurations a concrete pour requires.

Another advantage of GFRTP rebar is the ability to create surface deformations on it with secondary processes, according to Roberto Lopez-Anido, a University of Maine professor and member of the thermoplastic rebar research team at its Advanced Structures & Composites Center (ASCC). Adding ribbing or twisted fibers to the rebar’s surface, for example, could create texture that would help improve the bond between rebar and concrete.

ASCC researchers designed and built a new continuous forming machine (CFM) that made it possible to produce rebar through a non-reactive thermoplastic pultrusion process. The CFM may be the key to overcoming the scalability and production issues that have been a problem with some other thermoplastic pultrusion processes.

ASCC’s non-reactive pultrusion process begins with towpregs or pre-impregnated fibers that are fed into a guidance system. The material is then heated to the desired consolidation temperature of the thermoplastic polymer. The heating source makes the process efficient and reduces the time the material remains in the consolidating die that shapes it into the desired profile or sheet.

Next, the material travels into the cooled die where, depending on the type of polymer used, water or air cools the pultruded profile below the glass transition temperature in a controlled manner. The profile is then cut to the desired length.

The researchers used polyethylene terephthalate-glycol (PETG), an amorphous copolymer of PET and E-glass fibers for this process. “The advantages of PETG being amorphous is that it is not sensitive to cooling, so we do not have problems with crystallization. But we need to deal with the viscosity of the material, and being amorphous, it doesn’t have a well-defined melt temperature. That requires some calibration of the process,” says Lopez-Anido.

ASCC’s thermoplastic pultrusion line has been designed in modular form so that researchers can change the heating, cooling and consolidating processes depending on the type of thermoplastic material combinations that they want to use.

The team has done some initial testing of the GFRTP pultruded rebar, looking at factors such as the shear transfer between the rebar and the concrete, the properties of thermoplastic rebar with different diameters and materials, and its performance in reinforced concrete beam failure tests. Over the next year, researchers hope to obtain funding to compile a comprehensive database of these and other properties of the rebar, including its tensile strength, environmental durability, moisture absorption and reaction to alkaline environments. They will also develop a process for heating and bending the rebar on site.

Lopez-Anido says other issues that need study include thermoplastic creep and deformation and the type of protection that might be needed to shield the rebar in the event of a fire.

ASCC’s research has already shown GFRTP pultruded rebar could provide many benefits as an alternative to traditional rebar. Sustainability is one big plus. In addition to thermoplastic rebar being recyclable, it is made using a low-VOC continuous manufacturing method that reduces environmental impact and health risks.

Another thing that could make thermoplastic rebar attractive to the construction market is its competitive price. Lopez-Anido estimates the cost of producing the pultruded thermoplastic rebar with the CFM would be 60 cents a foot, which is in the same price range as traditional rebar.

Bending Thermoplastic Reinforcements

Over the last three years, researchers on the DRIFT project, funded by the German Federal Ministry of Education and Research, have explored the integration of load-bearing elements in an injection molding matrix. Composite parts produced through this process might be used for structural automotive parts and for parts that reduce a vehicle’s noise, vibration and harshness (NVH).

DRIFT’s goal was to show that a process combining thermoplastic pultrusion, industrial wire bending and injection overmolding was feasible. Researchers at Fraunhofer IGCV, who focused on the thermoplastic pultrusion step, worked with other development partners to successfully develop this combined production technology.

During the project’s first year, the researchers compared the benefits and disadvantages of three pultrusion processes: melt, mingled yarn and reactive. They eventually chose the melt pultrusion process because of the variety of materials that could be used in it and its higher predicted bonding in the injection-molded process. The challenges of melt pultrusion were scalability, melt viscosity, tooling complexity and the additional investment required for an extruder.

The team initially used a combination of glass fiber and polypropylene (PP) to manufacture the pultruded profiles. Later in the project, to further test the process and the properties of other material combinations, they combined glass fibers with polyamide 6 (PA6) and then carbon fibers with PA6 and PP. Researchers tested all the combination samples for fiber volume content, tensile properties and bending properties.

“The process isn’t limited to the four material combinations we used,” says Maximillian Rieger, group lead in pultrusion at Fraunhofer IGCV. He expects it will take just a few weeks to make the necessary adjustments to optimize the process and find the right temperatures for a variety of other materials. Options could include PEEK or PAEK, which might lead to the technology’s application in the aerospace industry.

The DRIFT team worked with equipment manufacturer WAFIOS to develop a bending machine for shaping the thermoplastic pultrusion rod into the desired shape for the automotive part reinforcement. Once the rod was bent, it was ready for the overmolding process.

With the use of automated technology, the researchers demonstrated that it is possible to pultrude, bend and insert thermoplastic reinforcements into automotive parts in a relatively short time. In addition, efficient raw material utilization would result in very little scrap.

“In the end, the DRIFT project was basically lessons learned from all the different partners and all the different work packages,” says Rieger. “We identified the weaknesses and the things that we need to work on.” The group applied for funding for a three-year follow-up project to take the process to a higher technical readiness level and push it into the industry for mass production.

The introduction of any or all these thermoplastic pultrusion processes to the market could provide customers in automotive, aerospace and other industries with another valuable tool for composite parts manufacturing.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.

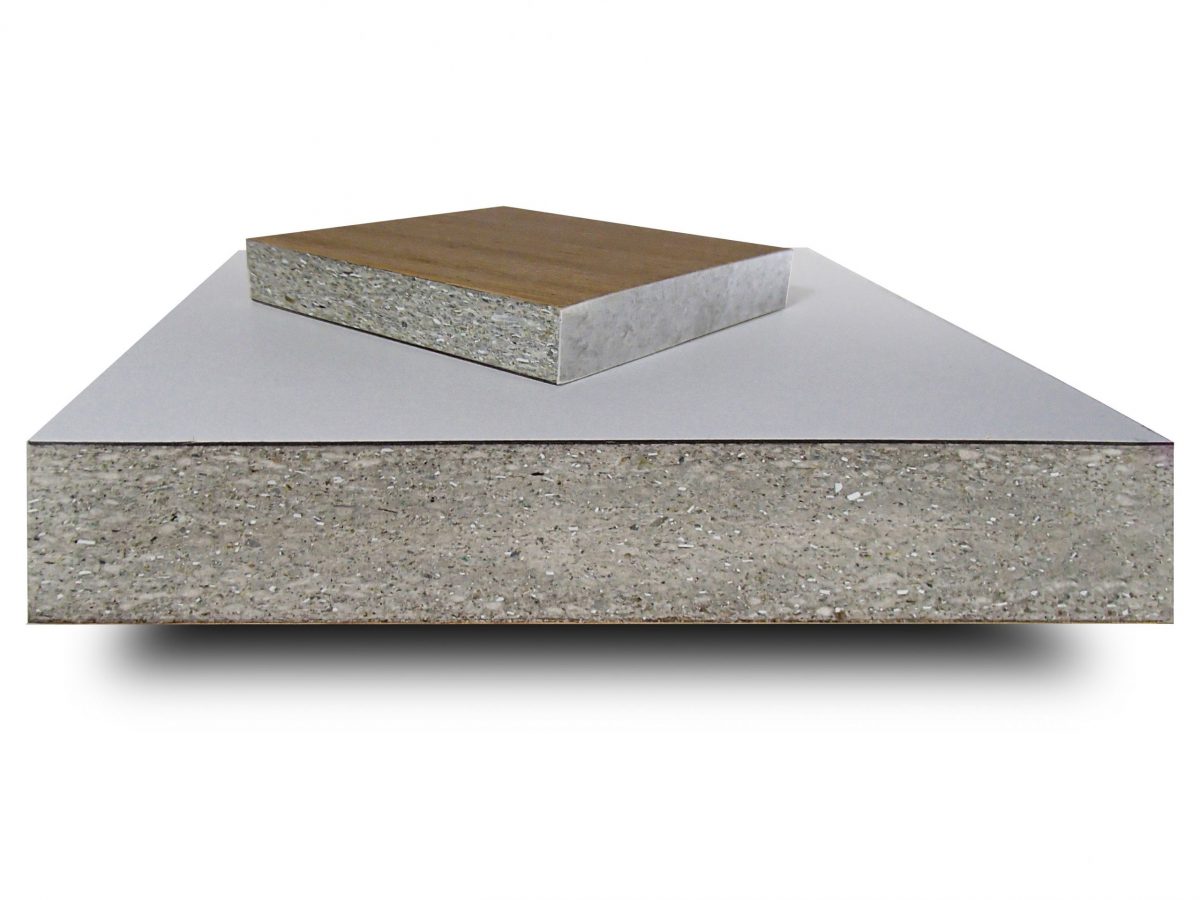

Researchers at Fraunhofer Institute for Chemical Technology ICT used a reactive process to produce pultruded, thermoformable profiles.

Photo Credit: © Fraunhofer Institute for Chemical Technology ICT

Researchers at the University of Maine’s Advanced Structures & Composites Center developed a continuous forming machine that produces pultruded thermoplastic rebar with PETG.

Photo Credit: Roberto Lopez-Anido

The equipment developed by the DRIFT project researchers for pultruding glass fibers and PA6 could be adjusted to handle other fiber and resin combinations.

Photo Credit: Maximilian Rieger

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.