A Second Life for Wind Blades

Developing new methods of recycling composite wind blades is taking on greater urgency as the U.S. becomes more reliant on this natural energy source. By 2050, the country could be dealing with 200,000 to 370,000 tons of composite end-of-life wind blades, according to a 2020 study conducted by ACMA for EPRI, a non-profit energy research organization.

Researchers from the composites industry, universities and government laboratories in the U.S. and Europe are collaborating on wind blade recycling projects that focus on finding new purposes for the reclaimed materials.

One of the biggest challenges is recovering materials that have market value. During the past year, wind blade manufacturer TPI Composites (TPI) worked with University of Tennessee, Knoxville (UTK) researchers to convert short-length glass fibers reclaimed from wind blades into performance-quality continuous technical yarns. “It would bring back some of the functionality of the virgin glass in the unidirectional tow and in spools,” says Stephen Nolet, TPI’s senior director of innovation and technology.

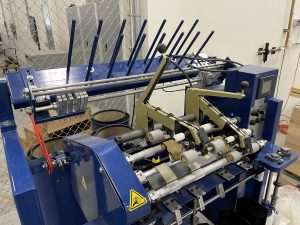

The glass fibers, recovered through a pyrolysis process developed by Carbon Rivers, ranged in length from a half inch to seven inches. Using slightly modified textile industry carding and spinning equipment, researchers comingled these short fibers with continuous synthetic filament to increase the fibers’ surface friction, holding the yarn together. A small rocket, filament wound with the yarn, was showcased at CAMX 2022.

Nolet says this process would likely work using other types of blade recycling processes and material sources, such as waste from non-crimp fabric cutting. The recovered fibers could be combined with almost any polyester or rayon synthetic fiber that improves their surface friction.

In the second phase of the project, which will take place over the next year, TPI will work with UTK at the Manufacturing Demonstration Facility at Oak Ridge National Laboratory (ORNL). They will produce larger quantities of yarn and test its properties.

The yarns could take several forms. “We can make simple uni-directional laminates, or we could braid them or wind them; that will be part of our process. We will then investigate them to see what yields the highest properties and then optimize those properties,” Nolet says. “I think one killer application would be the use of an acrylic synthetic fiber that’s comingled with recycled glass fiber to make a combination acrylic and glass yarn. You would then have a material system that you can thermoform.” This new material could be used for industrial and automotive applications.

TPI plans to make the technology available across the value chain. “We want to create the highest value for the end-of-life products that we’re building, so that these pathways become available,” says Nolet. “The market forces could take these innovative technologies and create new industries that will use our end-of-life products as feedstocks. It will reduce the cost of disposing of our products for our customers, make our products more sellable and create a true circular economy.”

Another possible market for reclaimed fibers is cured-in-place pipe (CIPP) liners, a hardened synthetic fiber tube that’s used to reline and rehabilitate existing water mains and waste lines. These tubes are often made with non-woven polyester felt, thick polyester resin and sealing agents that can close off any cracks in a pipe and help restore its structural integrity.

TexTech Industries and Carbon Rivers worked with TPI on a project that added reclaimed short glass fibers to the polyester mats. “The use of the glass fibers with the polyester tripled the strength of the resulting liner and doubled its stiffness. That means you can make a much thinner liner for a cured-in-place pipe and you’re using a lot less resin,” says Nolet. It also provides greater flow area for the pipe.

Maximizing Properties of Reclaimed Fibers

Glass fiber reclaimed from a wind blade would have a higher resale value if it could be recovered with minimal further degradation of its properties. Startup company Windfall, a spinoff from composites recycling research being conducted at UTK, developed a process that might make this possible.

“One of the main issues with using conventional pyrolysis for recycling is that the high temperatures can substantially damage the fiber you’re trying to recover. It’s not as big a deal with carbon fiber, but it is a very big deal with glass fiber,” says Ginder, a research assistant professor at UTK and co-founder of Windfall. In addition, the purity of the recycled fiber is relatively low.

But alternative recycling methods, like shredding wind blades to use as aggregates in panels or cement, take a lot of effort and yield a product with very little value, he says. “You lose the aspect ratio of the fiber that provides the mechanical performance, and you’ve got tons of contaminants like random resins and foams,” says Ginder.

To find a better method, Ginder first measured the characteristics of the fiberglass during the initial composite material manufacturing process and then after recovery through pyrolysis. Although pyrolysis initially looked like it was causing huge losses in the fiber’s tensile strength, “people weren’t taking into account that the fiber was getting damaged during the original manufacturing process,” he says. His research showed that glass fiber can lose up to one-third of its tensile strength during initial manufacturing. Therefore, the composite recycling process needs to avoid damaging it further.

Ginder developed a novel, multi-stage pyrolysis process designed for complete carbon separation from the embedded composite glass fibers. “The process removed the residual material without imparting additional damage to the glass fiber,” he says. The resulting white, fluffy fiber can be reused in a variety of different processes.

“The fiber doesn’t have the same spec values as virgin fiber, but it does have the same approximate stiffness as virgin fiber. The strength is still less, but it’s relatively close to what it was when we received it,” he adds.

Windfall has since been folded into the operations of another recycling company, and UTK plans to publish findings on this technology soon.

Making the move from research to marketplace remains challenging. “There is a value with glass fiber, even though it's substantially less than carbon fiber. But you need to reach a certain scale in order to both have a large impact on waste and also to be able to reach economies of scale,” says Ginder.

Reusing all Materials

Continuum, based in Denmark, has developed its own approach to wind turbine blade recycling. Co-founders Reinhard Kessing, Jesper Kilbaek and Nicolas Derrien, together with CEO and Interim Chair Martin Dronfield, have extensive research and practical experience in the composites recycling sector. With the assistance of technical and wind industry experts, they created a patented mechanical recycling process that they say can reclaim virtually all of the different raw materials from wind turbine blades and transform these recovered materials into new, high-performing construction panels.

“A wind blade consists of up to 10 different materials, so chemical recycling all of these streams into one place will never be sustainable because you need so many processes,” says Hülya Ucar, materials and recycling specialist at Continuum. “With mechanical recycling, we can do everything in one process. It is a technology that can solve this problem in a way that is environmentally sustainable and also economically feasible.”

Wind blades, thermoset composites and glass fiber or other non-metallic fiber materials bonded with epoxy, polyester, polyurethane and vinyl ester resins can all serve as feedstock for the process. Fines (crushed or powdered material) and fibers from manufacturing waste can also be recycled.

“The feedstock is fed in large pieces into the factory, where it is crushed and then fed through a series of cutting, milling, separating, sorting, screening, sifting and cleaning sub-processes until pure, clean material is put into storage hoppers,” says Derrien, chief investment and development officer of Continuum. The polyurethane fillers and epoxy resins that are detached from the glass fibers are segregated in fine, granulated form.

Continuum’s method also separates out more than 90% of any carbon fiber embedded into the wind blades. It’s then sent to companies that specialize in carbon fiber recovery. Copper, aluminum, non-ferrous metals and small contaminants like stones or pieces of rope are either recycled or disposed of.

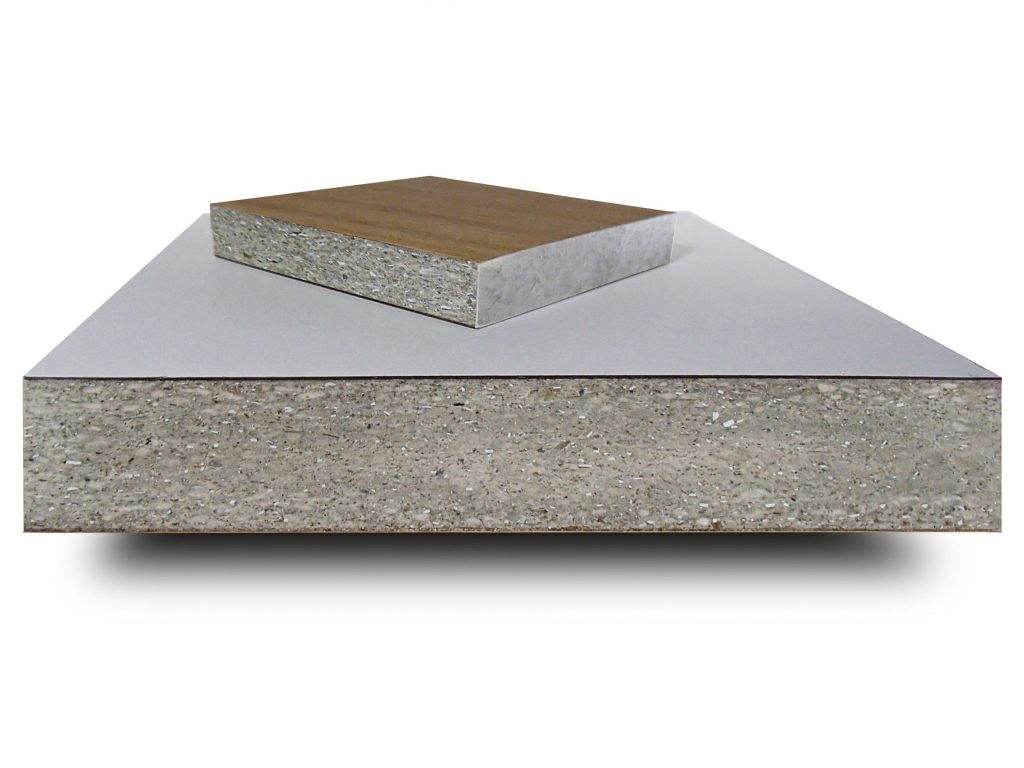

In the second stage of the process, the materials that have been separated into different silos are mixed, with a low percentage of virgin resin mixture, to form a new type of composite material. “We have about 20 different properties that we can adjust, some more than others, based on the performance requirements for each panel,” says Derrien.

The third step is the formation of the panels, which are themselves fully recyclable. The formaldehyde-free panels can range in thickness from .23 to 1.5 inches and are manufactured in the same lengths and widths as competing wood fiber or cement panels. Continuum’s products are moisture-resistant and have a strength comparable to or higher than their conventional counterparts, Derrien says. They are a good choice for building facades and for floors and countertops in bathrooms and kitchens. Customers can finish the panels with paint or another coating.

Continuum’s first factory will open in Esbjerg, Denmark, by the end of 2024, with a second factory in the United Kingdom not far behind. The company also plans to build factories in France, Germany, Spain and Turkey by 2030. Each factory should be able to manufacture 30,000 cubic meters of the new composite panels each year while recycling 36,000 tonnes (approximately 79.4 million pounds) of end-of-life composites.

Derrien says Continuum’s process is energy efficient, sustainable and cost-efficient, which makes it competitive in both the feedstock and end product markets. “It is a green product that is becoming a key differentiator in an industry looking to de-carbonize,” he says.

Increasing the sustainability of composite materials is essential to the industry’s future. Although the challenges of dealing with end-of-life wind blades won’t be resolved quickly, the number and variety of reclamation methods being developed today hold promise for viable solutions in the not-too-distant future.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.

The glass fibers recovered from the University of Tennessee, Knoxville’s new modified pyrolysis process are purer and more valuable for commercial applications than those recovered in a traditional pyrolysis process, according to university researchers.

Photo Credit: Ryan Ginder, UTK

Rolls of nonwoven fabrics, made from recycled glass fibers recovered through UTK’s modified pyrolysis process, can be used in applications like boat construction.

Photo Credit: Ryan Ginder, UTK

TPI, Carbon Rivers and UTK developed modified versions of a textile carder and spinner (shown here) to create a blended recycled glass fiber/continuous synthetic filament yarn with promising properties.

Photo Credit: Steve Nolet, TPI

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.