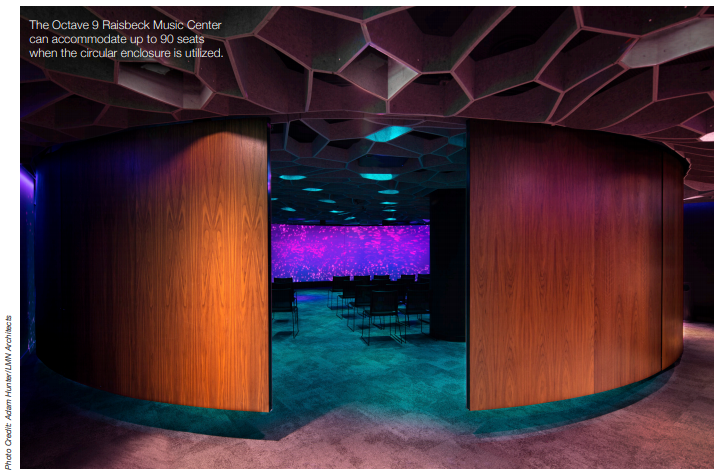

CFRP Panels Encircle Symphony Audiences

Audiences in the Seattle Symphony’s new Octave 9 Raisbeck Music Center are surrounded by a CFRP-backed circular enclosure that immerses them in a multi-sensory experience of live music, surround video projection and responsive audio and acoustics. Opened in February 2019, the 2500-square-foot music center is designed for intimate performances, educational programs and community engagement offered by the symphony. The CFRP panels, which were formed from repurposed carbon fiber epoxy prepreg scrap and finished with black walnut veneer, were chosen as a lightweight alternative to acrylic.

“The issue that we came up against was that we had specified an acrylic panel – something like a 3/8-inch thick – and it was going to be really heavy,” explains Scott Crawford, Octave 9 project designer with LMN Architects in Seattle. He recalled seeing a CFRP/wood veneer sample and thought this would be a way to include wood that matches the hall’s existing woodwork, while significantly reducing the weight of the entire structure.

Weight was especially important because the music center features 13 movable sections, which allows the symphony to adapt the space and sound by using a few panels or creating a nearly complete circle. Each section comprises a CFRP-backed black walnut veneer exterior panel and an interior acrylic video screen panel. The panels are mounted on either side of a wheeled steel frame so they can be easily moved.

The panels are the creation of the Composite Recycling Technology Center (CRTC) in Port Angeles, Wash., a nonprofit organization dedicated to developing products from advanced composite scrap material. Such material is abundant in Washington, with approximately 900 tons of carbon fiber composite manufacturing waste sent to landfills annually, according to the Washington Department of Ecology. CRTC estimates that includes approximately 500 tons of uncured carbon fiber prepreg.

CRTC procures CFRP prepreg from a handful of companies, including Toray CMA and Boeing. The scrap is generated when manufacturers clear expired prepreg from their freezers or reject material because of cosmetic flaws, such as a missing a fiber or a slice in the roll. Material suppliers also discard partial rolls of CFRP prepreg left over at the end of production runs. “That’s pretty common, especially with full-width rolls,” says Erik Poulin, CRTC materials process engineer. “At the end of a bunch of production runs, they’ll accumulate the leftovers onto one roll and then that will get scrapped.”

Poulin says that reclaimed prepreg, such as that used in the Octave 9 project, retains most of its properties, cures well and generally looks and acts like virgin material. “As long as you don’t need the paper trail like aerospace requires, it’s still a really beautiful material,” he says.

The Octave 9 panels were manufactured from reclaimed unidirectional Toray carbon fiber epoxy prepreg using a quasi-isotropic layup, standard vacuum bagging process and 250 degrees Fahrenheit oven cure for 120 minutes. The 10 x 10-foot panels were then trimmed to their final 7.5 x 8-foot size using a water jet. “The water jet gave it a nice finish, and we were also able to put the hole pattern [for fasteners] in really precisely, which made the assembly a breeze for them,” Poulin notes. The black walnut wood veneer, which was stained to match existing wood in the music hall, was cut to shape with a veneer saw and bonded to the CFRP panel with contact cement.

The size of the panels presented a few challenges. “It’s pretty rare for a company our size to be doing 10 x 10-foot parts,” says Poulin. “Those are pretty big parts, and having good cosmetic properties and getting compaction across the part can be tricky.” Applying veneer to such large panels was also a new experience for CRTC.

Crawford says that the CFRP panels provide numerous advantages over the originally specified acrylic ones. Foremost is weight savings. He calculates that the 30-pound CFRP wood veneer panels provided an 83% weight reduction, making them easier to install and move. They also added shear strength, stiffening the entire structure and reducing bouncing and vibration when the sections are wheeled through the hall. The 1.4-millimeter-thick panels could also be bent into shape, eliminating the need for an expensive curved mold. “The entire assembly of carbon fiber and wood veneer was flexible enough that they could just bend it to fit onto the back of the frame, and that kept the overall cost down,” Crawford stresses.

Using scrap prepreg also reduced costs, making it possible to even consider CFRP. “One of the biggest challenges to the use of composites in architecture is the up-front cost of the material, and oftentimes if you’re not going to get a significant benefit from either the light weight or the corrosion resistance, then it’s hard to make it pencil out,” says Crawford. “But in this case, since [CRTC] is getting this stuff and reusing it, it lowers that initial cost, so it made it more possible for us to explore.”

Poulin stresses the cost savings as well. “It’s pretty unique to switch to carbon fiber and still be within budget,” he reflects. “I think that’s the biggest takeaway – that we were able to show that repurposed carbon fiber is economically feasible.”

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.