Continued Growth in Consumer Goods

Strong, durable and lightweight composite materials are a natural fit for the consumer products industry. From sporting goods to home appliances, composites are increasingly used for many applications.

Manufacturers of cell phones, tablets and smart watches are reducing the size and weight of their products because they can use very thin, durable and impact-resistant composite materials for casings. Companies that specialize in athletic shoes are incorporating carbon fiber into the plates of running shoes, providing a lightweight stiffness that can boost performance. In addition, layers of carbon fiber composites in basketball shoes add cushioning that absorbs shock and reduces stress on the player’s body.

Here are a few detailed examples of how composites are transforming consumer products today, and a preview of some material innovations that could help the industry gain an even greater share of this market in the future.

A Better Ride for Boarders

The bindings on a snowboard are key to the quality of the ride that snowboarders enjoy. Bindings transfer riders’ muscle movements to the board, enabling them to control it. For the best snowboarding experience, the highback of the binding – the heel-side ankle support – needs to be strong and durable, but also extremely lightweight with just the right amount of flex.

The design team at Rome Snowboards wanted to create a new, highly-advanced binding for its portfolio. Material supplier Avient suggested a binding made using a thermoplastic injection overmolding process. The company’s advanced composites technical team worked with Rome Snowboards to determine the right material, testing various combinations of engineered resin and reinforcement, fiberglass content and laminate configurations.

Avient found the sweet spot in its Polystrand™ eight-ply fiberglass reinforced polyethylene terephthalate glycol (PETG) laminate overmolded in nylon. The fibers in Polystrand lay flatter than a traditional woven composite, which provided additional durability to the binding component. The PETG resin helped ensure the binding had the flexural strength and impact resistance that Rome Snowboards required.

Rome says its Black Label binding, introduced to the market in 2021, is the lightest and most responsive binding it has ever produced.

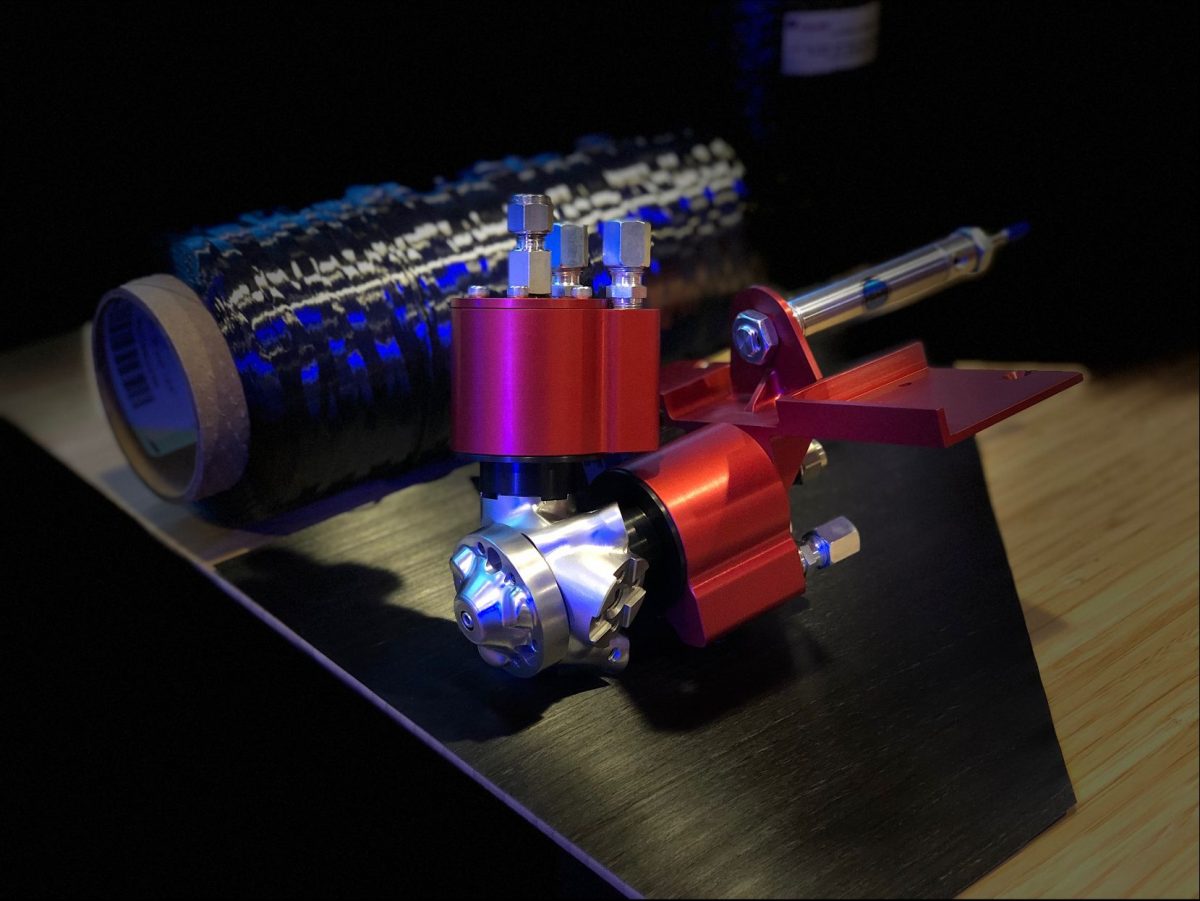

Metallic Appearance, Composite Advantages

Kitchen appliance manufacturers still rely primarily on metal for refrigerators, stoves, dishwashers and ovens. But for certain components, such as control/console panels, door trims, handles and knobs, composites are the material of choice.

“Composites do exceptionally well in cooking products, whenever you have heat, dimensional stability issues and design constraints,” says Scott Balogh, president and CEO of Mar-Bal, which compounds, molds and finishes thermoset composite products.

To increase the size of the oven cavity, for example, manufacturers have cut down on the thickness of the insulation. To protect oven users, they must use materials on the exterior that don’t retain heat. Mar-Bal manufactures oven door vents, control/console panels, handles and decorative trim parts that help keep an oven’s exterior surfaces within UL’s touch temperature standards.

“Oven doors and console panels have been a huge growth area for us,” says Balogh.

When selecting appliance components, manufacturers also require a material that can easily accommodate constantly changing kitchen design trends. Stainless steel finishes have been the top choice for more than a decade, but other finishes, like black stainless, copper and bronze, are popular as well. Composites manufacturers can provide the desired finishes using physical vapor deposition (also known as vacuum metalizing).

Mar-Bal calls its proprietary process THERMITAL. The composite components are placed in a large vacuum chamber, and atomized metals are deposited on their surfaces in a thin film. By using different types of gases during the application of the metal, Mar-Bal can achieve a variety of colors similar to conventional coatings: stainless (silver, black and blue, both shiny and matte), tin, aluminum, titanium, copper and brass.

The metallized coating – about the thickness of a human hair – is covered by a sprayed-on, ultraviolet curable paint. It’s a non-solvent coating, so it’s an environmentally friendly process.

Although physical vapor deposition has been used for the reflective back sections of vehicle headlamps for almost a decade, it’s only within the past five to seven years that appliance manufacturers have become more interested in this usage, according to Balogh.

Futuristic Furniture Forms

Based in Italy, the style capital of the world, Mast Elements says it is the first company in the world to produce carbon fiber furniture.

“Carbon fiber has many advantages; it is five times stronger than steel and much lighter,” says Marco Cighetti, the company’s export manager. “Thanks to these features, we can provide unusual designs that are otherwise impossible using other materials.”

Mast Elements produces luxury indoor and outdoor furniture – sofas, chairs, tables and accessories – in modern, avant-garde forms. The carbon fiber material provides flexibility, enabling the company to design and manufacture products in many combinations of colors and finishings.

Producing CFRP furniture requires a long and detailed process, Cighetti says. The furniture is formed through a manual layup process, then processed in an autoclave to distribute the polymer in the fiber in a controlled and uniform manner. Once the piece comes out of the autoclave, any required finishing work and the spray application of the surface are done manually.

Mast Elements’ furniture offers some sustainability advantages in addition to its unique style, Cighetti adds. The carbon fiber can be recycled, and the machines used in the production process are eco-friendly. Because of carbon fiber’s strength and other unique properties, the manufacturer uses less material for a furniture piece than an equivalent, conventionally produced item.

This furniture is priced for the high-end market. “Our products have a lot of ‘made in Italy appeal,’ starting from the unique design, the high quality and the attention to details,” says Cighetti. The company sells its furniture globally through dealers and architects to boutiques, villas and hotels.

Sustainable Options on the Horizon

Consumers throughout the world are looking at the impact of their purchases from a sustainability perspective, according to a 2021 study from the global consultancy firm Simon Kucher Partners. Of the 10,000 people interviewed, 85% said that they had changed their purchasing behavior toward sustainability. The study also found that almost one-third of millennials will choose a more sustainable product when it’s available.

Applied Bioplastics has developed a technology that could enable the composites industry to offer more eco-friendly options for consumers who want to purchase products like pens, phone cases, coolers and more.

“Essentially, what we're making are biocomposites products with lower carbon footprints and better plastic,” says Colin Ardern, Applied Bioplastics’ CEO. “The main value proposition to our customers is reducing your carbon footprint without making an impact on your bottom line and using the same equipment that you're using today.”

Through careful selection of natural fibers and energy sources, the company says it can reduce the amount of CO2 generated in the manufacture of products made from composite materials by as much as 30% to 40%. Wherever possible, the company tries to use a renewable energy source like solar power and select fibers that have the maximum possible carbon sequestration. However, the choice of fiber will ultimately come down to the sustainable fiber that offers the mechanical properties sought after by composite manufacturers.

Applied Bioplastics specializes in the chemical and physical treatment of plant fibers to get them to the optimal form for compounding. It also does the compounding. “We have very specialized knowledge in designing additive packages to meet specific requirements, in compatibilizing the plant fiber with the polymer matrix, in creating a biocomposite that’s usable by our customer,” says Ardern.

While the biofibers the company produces can sometimes match the mechanical properties of glass fibers, that’s often not the case. But biofiber usually remains a viable option. “When we talk with customers to learn their requirements, what we’re finding is that in most cases we are able to meet those requirements,” Ardern says.

The company produces the biocomposites in pelletized thermoplastic designed for the injection molding machines that the composites industry is already using. The only manufacturing change required is slight adjustments in processing temperatures.

Recognizing the price sensitivity of the consumer goods market, Applied Bioplastics is creating its biofiber pellets to be competitively priced with existing products. That’s an essential factor in gaining widespread acceptance by manufacturers of mass market goods.

Applied Bioplastics is now testing the technology with about 20 consumer goods companies and preparing to build a large-scale facility to produce its thermoplastics pellets in 2022.

“We anticipate the brands will be signing capacity reservation agreements in the first few months of 2022,” Ardern says. Once the companies are using the biofibers in production, he expects they will emphasize the sustainability of this new approach in their marketing to consumers.

Mary Lou Jay is a freelance writer based in Timonium, Md. Email comments to mljay@comcast.net.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.