The Future Looks Bright

During her CAMX 2019 keynote presentation, Vicki Holt, president and CEO of Protolabs, praised composite materials as a game changer. “The amount of solutions that your innovations can bring are second to none,” she said. “Composites and advanced materials are one of the leading innovative industries that are going to continue to change the future.” When CAMX wrapped up in Anaheim, Calif., earlier this year, it was clear the future looks bright for the composites industry. Nearly 8,000 industry professionals attended the annual conference Sept. 23 – 26, visiting more than 520 exhibitors on the show floor and picking up invaluable insight at 48 educational sessions. One theme resonated throughout CAMX 2019: By embracing technological changes and Industry 4.0, the composites industry will continue to grow and play a pivotal role in several global megatrends. The Impact of Manufacturing 4.0 Manufacturing 4.0 is more than a lofty notion: It’s changing the landscape of manufacturing as we know it, and that’s a good thing, said Holt during the CAMX 2019 general session. “Technology and digitization can bring value to the products we make, can bring value to the workplace of our employees and can bring efficiencies to our plants,” she said. Founded 20 years ago, Protolabs is a manufacturer of custom prototypes and on-demand production parts with manufacturing facilities in five countries. It pushes the envelope of digital manufacturing to accelerate product development, reduce costs and optimize the supply chain. Holt provided insight on how to harness manufacturing 4.0. “If you think you can sit on the sidelines and not be part of this manufacturing revolution, I think you are wrong,” she said. “It will happen all around us, and we need to take advantage of the tools and think about how to use them to bring value into our businesses.” Holt shared 5 tools that are impacting manufacturing:

- Data Analytics and Computing Power – “Today, with all the data we can collect and the relatively inexpensive computing power that we’ve got, we can very quickly analyze a lot of data and put it through very complicated pattern recognition algorithms using multiple variables,” said Holt. Protolabs uses data to improve its efficiencies, optimize tool pathing, reduce waste and more.

- Augmented Reality – “Virtual reality is a tool many of us can use in our businesses,” said Holt. Protolabs utilizes it in its sheet metal business to train welders. Some companies use it to do jobs more safely and efficiently, such as checking out large pieces of equipment before they are shipped to customers.

- Automation – “Automation has been around for a really long time, and it’s not going away,” said Holt. “Robotics, sensors and co-bots – those that work right along an operator – are only going to grow.”

- Industrial 3D Printing – 3D printing represents about 13% of Protolabs sales revenue, and it’s growing faster than the company’s other services. “We are leaning into 3D printing,” said Holt. “We think it’s a great tool for manufacturers across all industry verticals.”

- B2B E-commerce – “I believe business-to-business e-commerce is a huge opportunity for the manufacturing space,” said Holt. “When you can connect with your supply chain digitally it takes out errors, you have a single record and a digital thread for quality purposes, and you always know you’ve got the right version because everything is digitally connected.” Protolabs uses a 100% e-commerce business model.

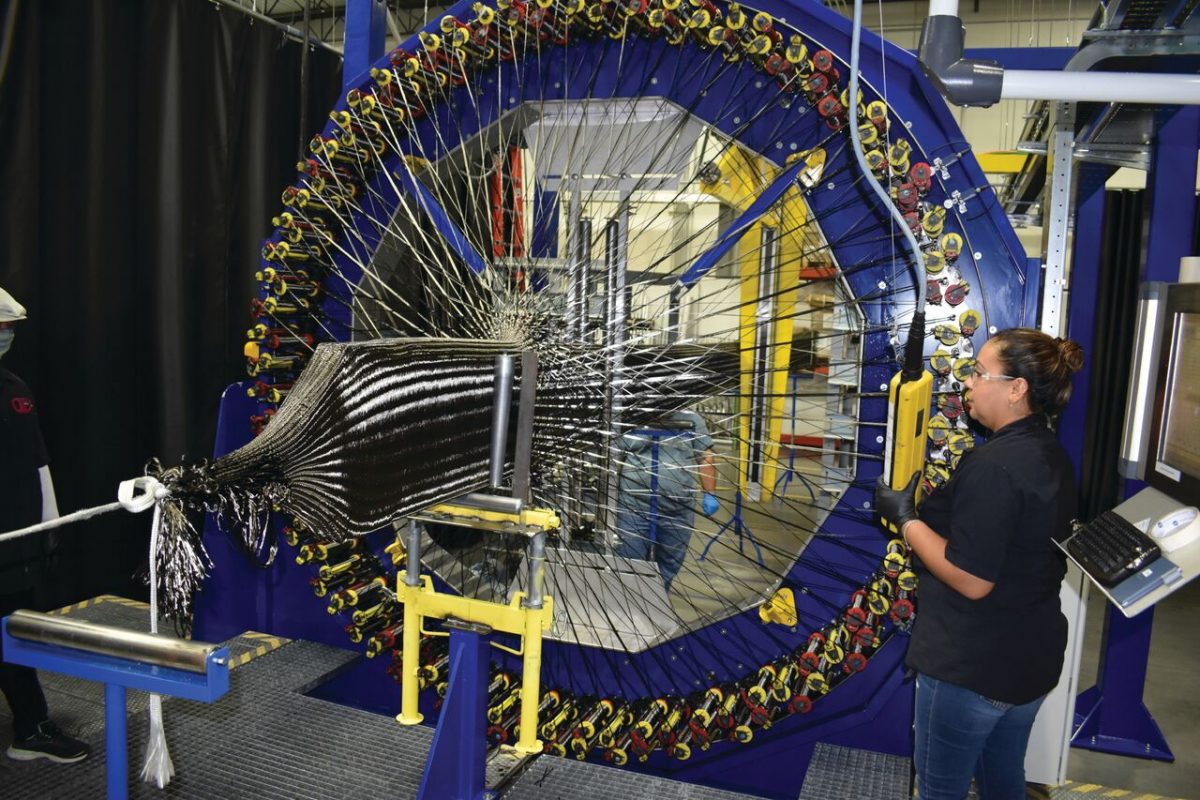

- Toolless Thermoplastic Parts: Mikrosam displayed a proof-of-concept toolless thermoplastic manufacturing process that uses dual robots to create thermoplastic parts without a mandrel. One robot lays up thermoplastic tapes using controlled angles, while a second follows the same path on the opposite side of the part to maintain its shape.

- Automated Patch Placement with Self-Corrective Quality Control: Cevotec’s new patch placement system is designed to help aerospace manufacturers automate. By placing different materials on complex surfaces – such as adhesives and prepreg glass fiber on honeycomb – the system can replace hand lay-up. It also uses cameras to check quality at multiple production points and correct any problems in real time.

- Fully-Automated Hydraulic Presses: Langzauner’s hydraulic presses help customers meet short cycle times through automated mold changing. Traditionally, changing molds – especially hot ones – is a time-consuming task that can take up an entire shift, while Langzauner’s automated process can do it in 15 minutes, according to the company.

- Trainable Robot for Spray Lay-Up: CAMX attendees gathered around the Composites One demonstration area to watch MVP demonstrate a new spray lay-up robot that can be taught without programming. The teachable, automated sprayer is currently used to manufacture boats, pools and other products.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.