Graphene-enabled Smart Composites are Detecting Structural Defects in Aerospace

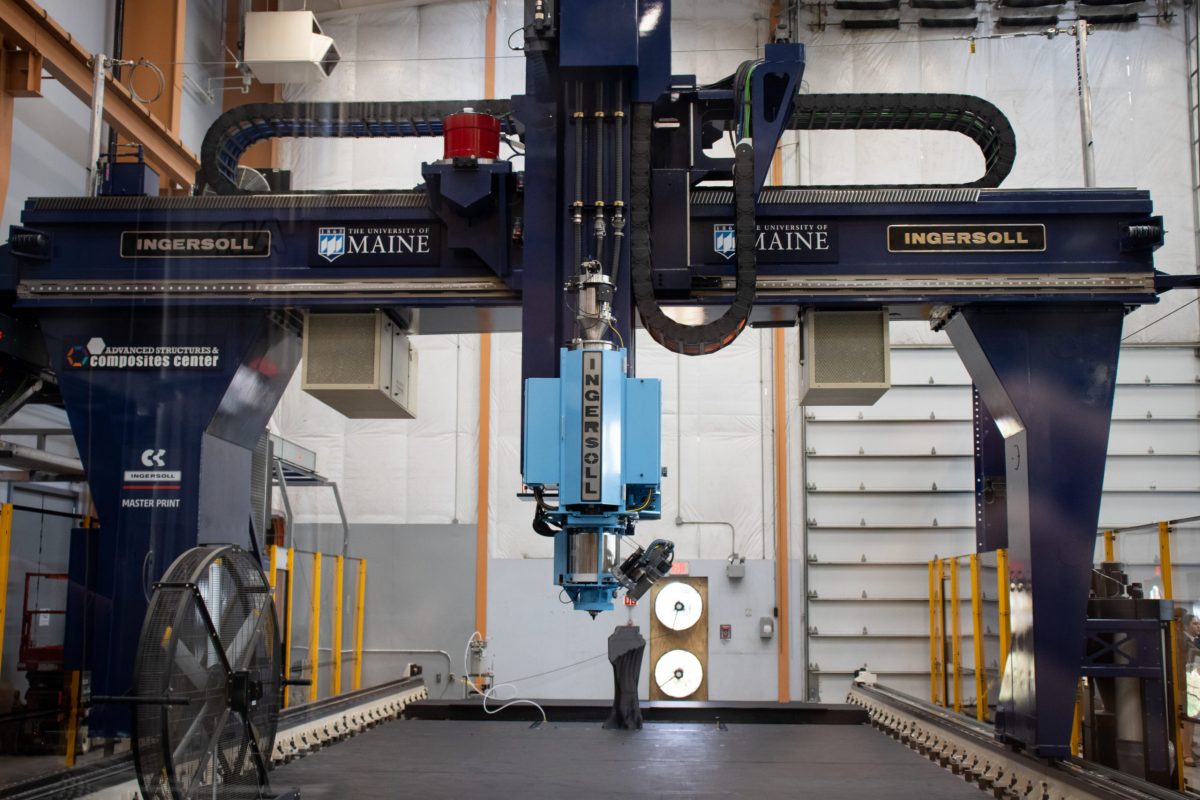

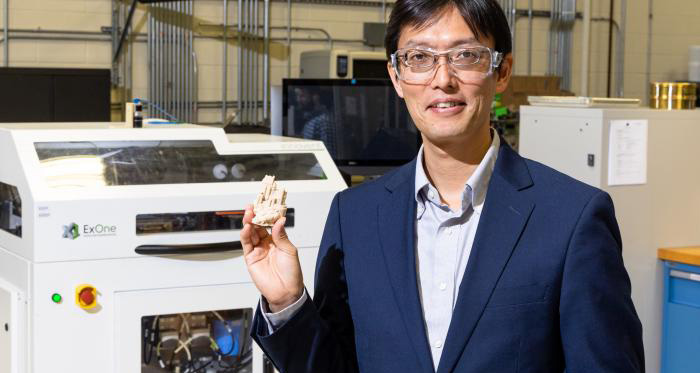

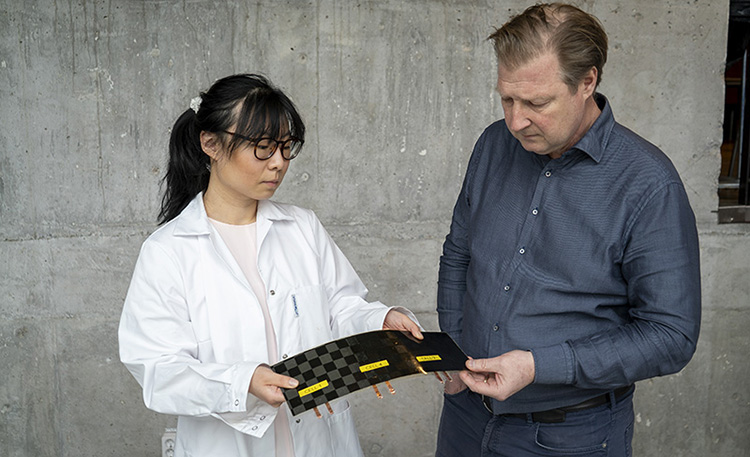

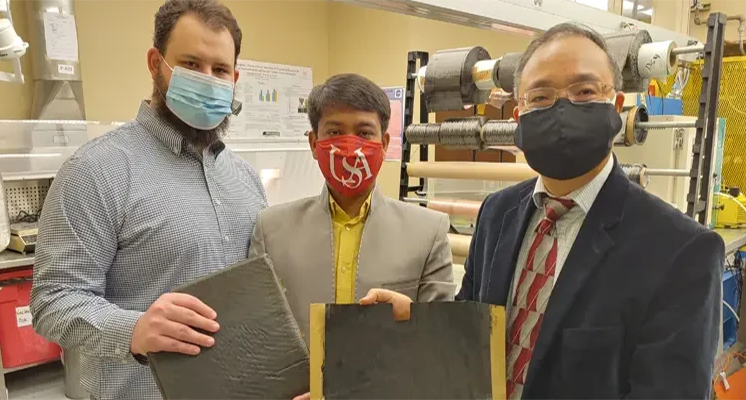

Researchers at Swinburne University of Technology and teams from Sparc Technologies and Composite Materials Engineering are creating smart composites that can save lives and save money by detecting structural defects in aircraft and rockets.

The project is funded by the Australian government’s Australian Research Council (ARC) through the Linkage Project program. The Linkage Program promotes research partnerships between researchers and business, industry, community organizations, and other publicly funded research agencies encouraging the transfer of skills, knowledge, and ideas as a basis for securing commercial and other benefits of research. ARC provided more than $1M for the project.

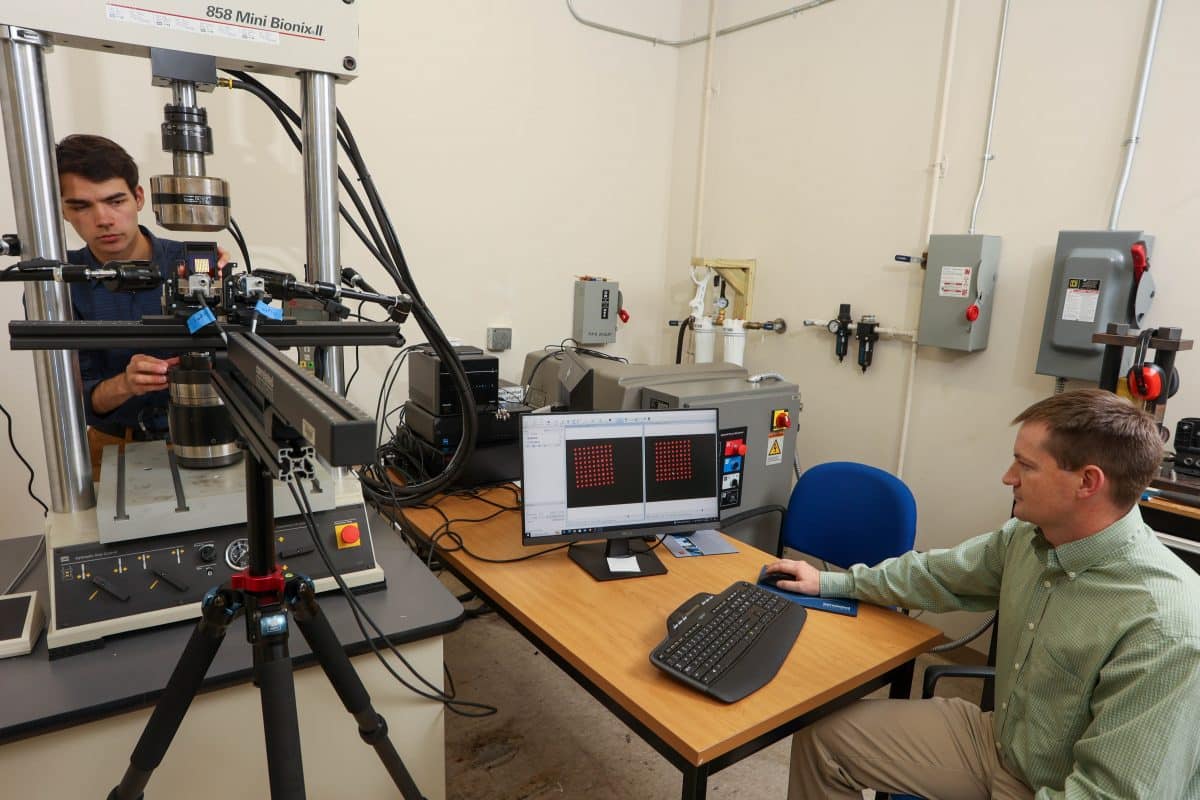

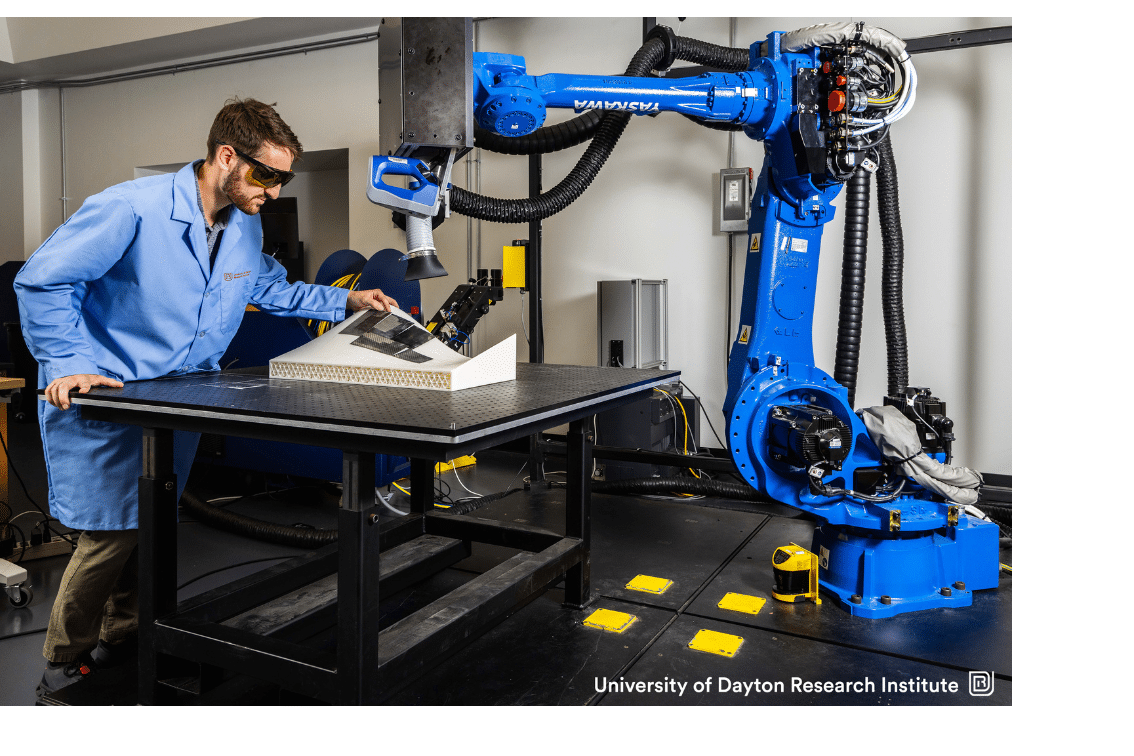

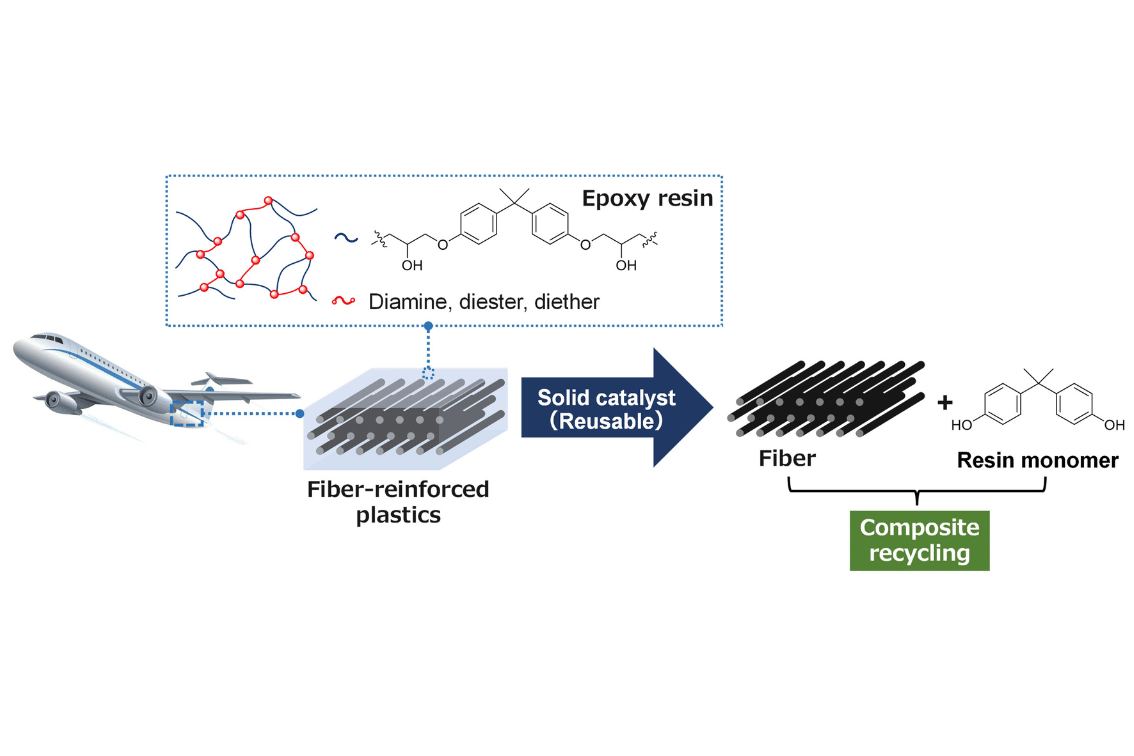

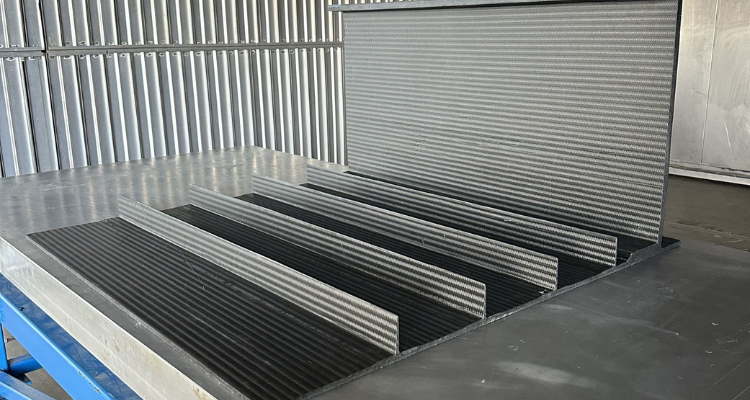

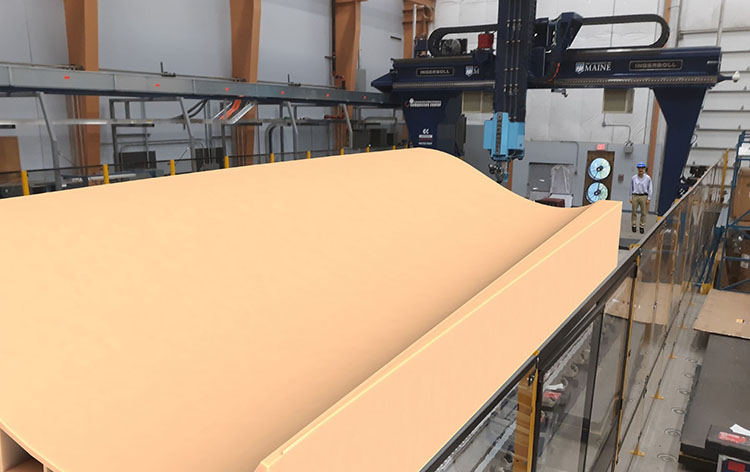

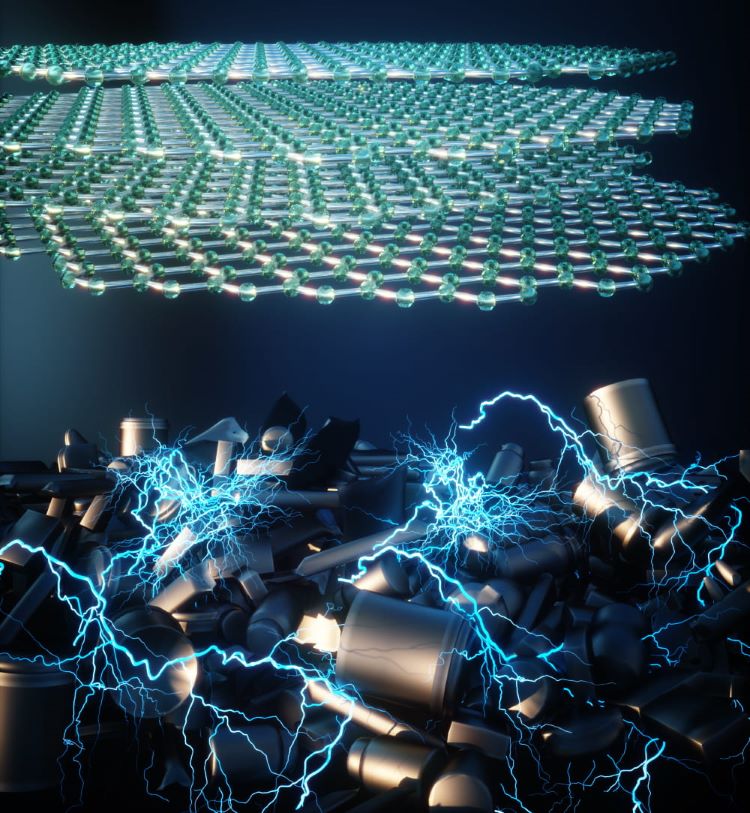

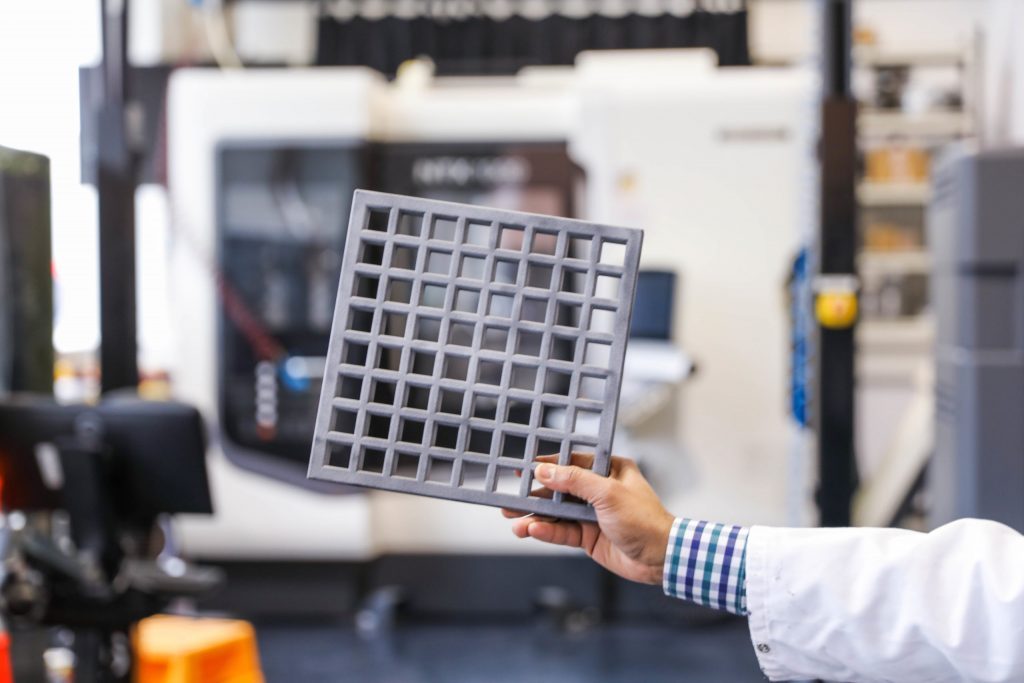

Graphene-based nanomaterials are used to create a working prototype that uses wireless connectivity to monitor maintenance needs and structural defects in aircraft components. Traditional carbon fiber structures can experience defects that cannot be detected by visual inspection. The technology could also be applied to monitor wind turbine blades in the near future.

“Working with Swinburne University of Technology, we are pushing the boundaries of what is capable in advanced manufacturing and graphene-based technologies to truly transform industries,” said Mike Bartels, managing director of Sparc Technologies.

“We are helping to create an interconnected network of smart composites that can transform how we build and maintain massive structures like airplanes and wind turbines,” said Lead investigator Associate Professor Nishar Hameed. “This technology could help address the massive cost – human, economic, environmental – of catastrophic disasters like airplane crashes, while delivering benefits across a range of industries.”

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.