Doors of Clean Sky 2 Program RACER Rotorcraft Built of Carbon Fiber

The RACER (Rapid and Cost-Effective Rotorcraft) combines the speed of a fixed-wing aircraft with the vertical advantages of a helicopter. Developed as a project of the European Union’s Clean Sky program, the RACER team also focused on sustainability goals. Plans are for the RACER, with a cruise speed of more than 400 km/h, to be used for search and rescue and transportation in medical emergencies as well as for urban air mobility.

“The RACER is a pretty complex machine with extra components. But despite all that the target is to develop a complete rotorcraft, aiming for demonstrating time-critical missions,” Antonello Marino, project officer at Clean Sky, explained. “A major aspect of the challenge is to reconcile the environmental targets — to reduce CO2 by 20%, NOx by 20% and noise by 20 — without adding weight. We need to add wing boxes and two lateral rotors to achieve the boost in speed, while staying within the weight envelope of a conventional helicopter. This means having to integrate new techno-bricks, lighter materials and innovative thinking.”

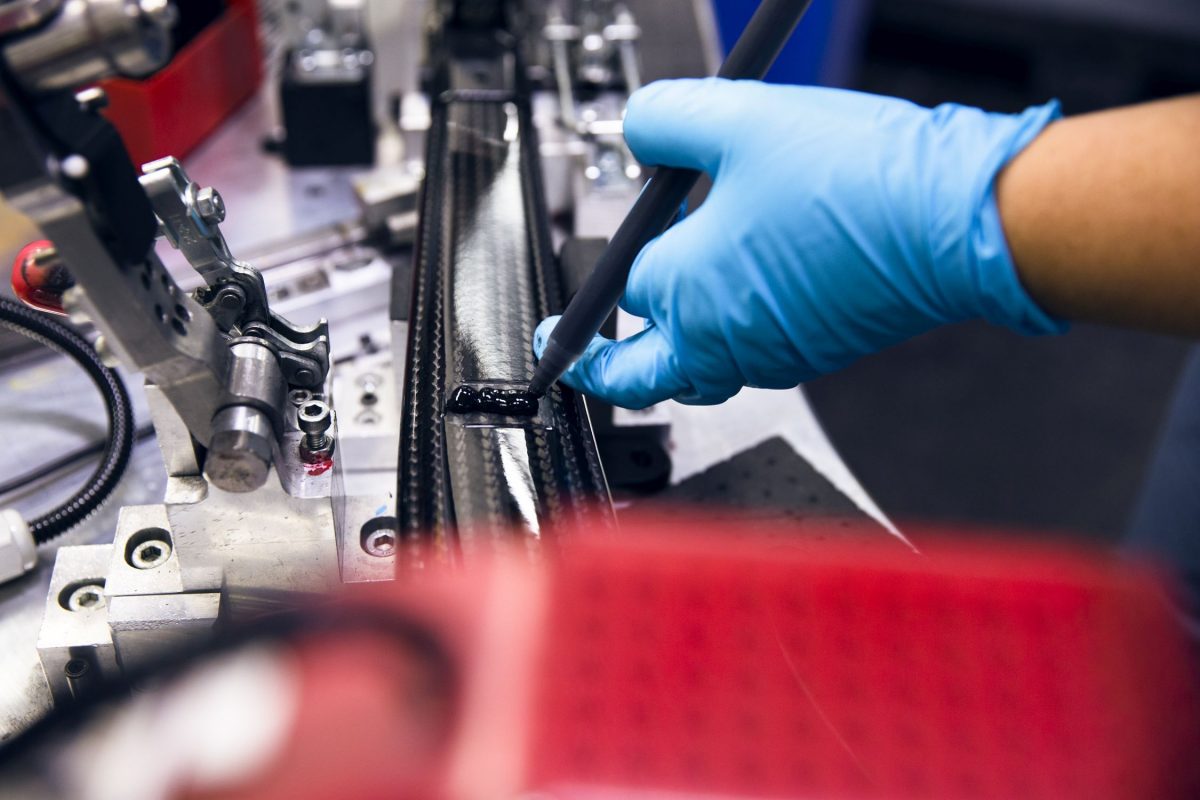

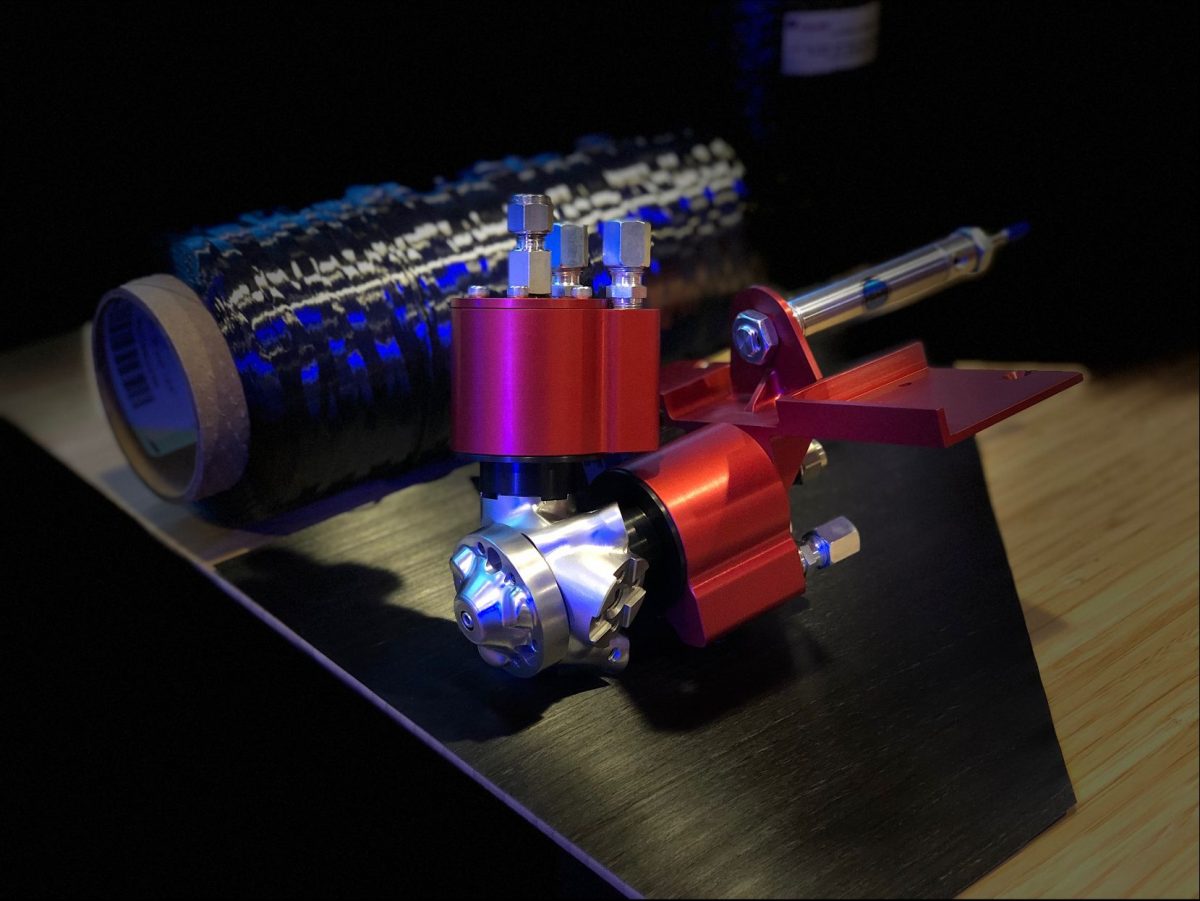

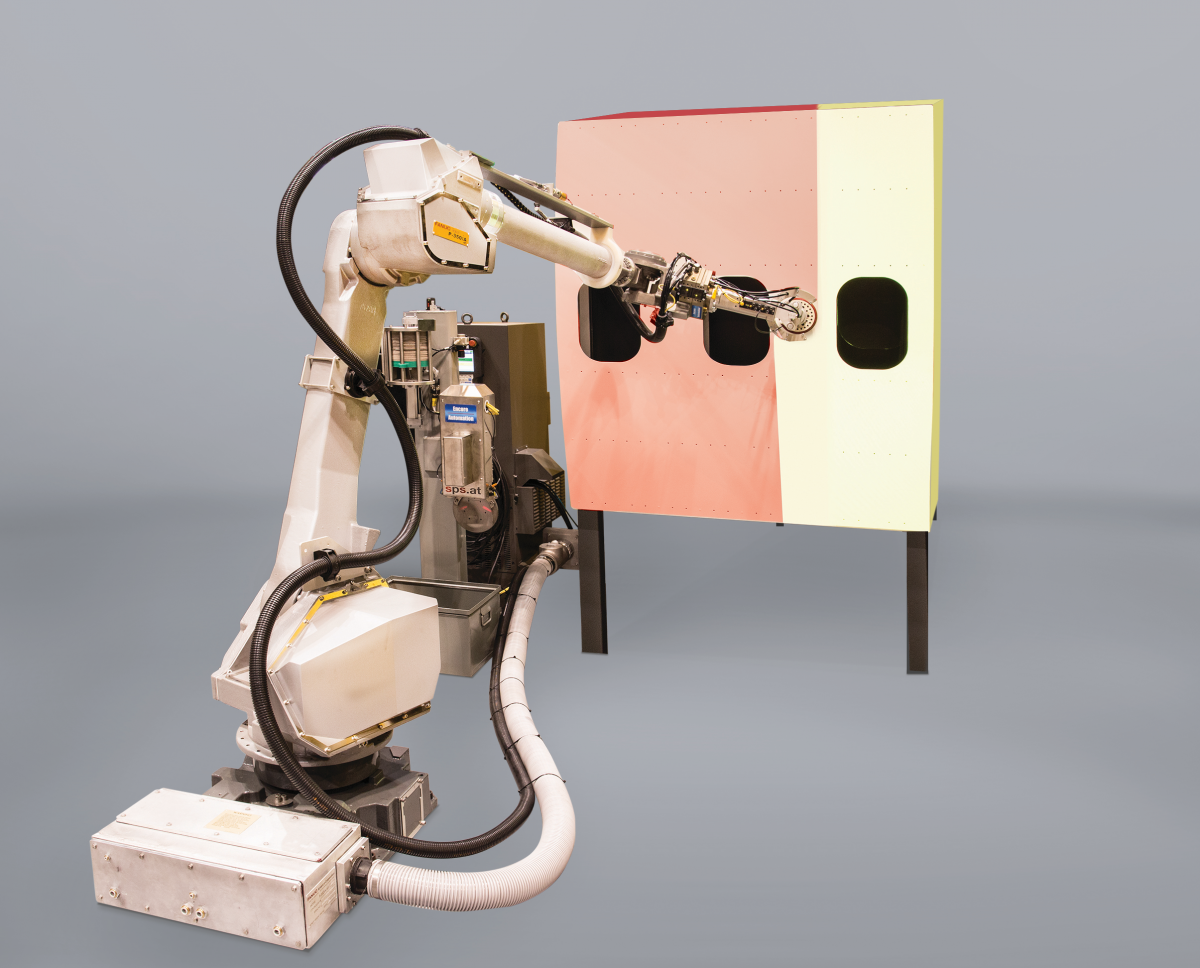

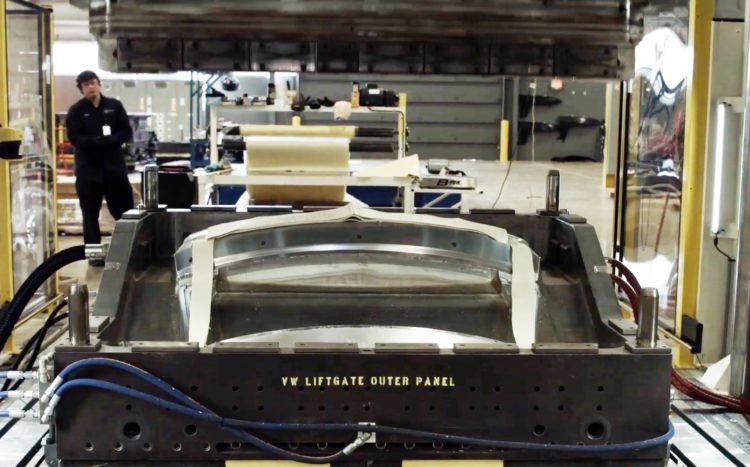

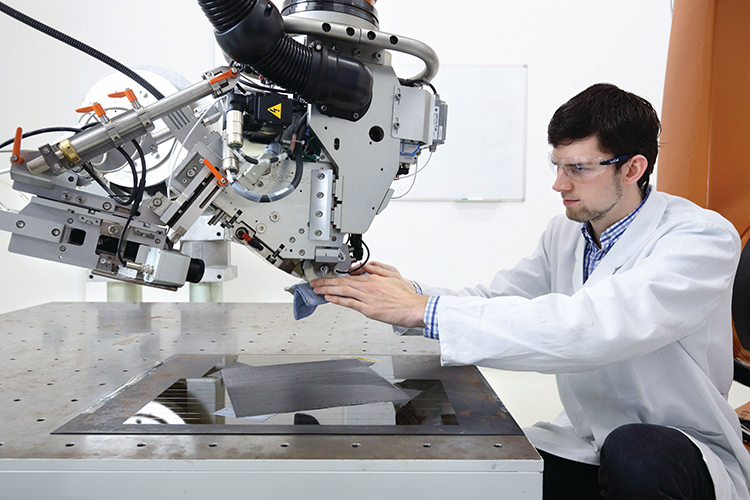

Keeping in mind the need to meet environmental goals while still providing lightweight, aerodynamic, and strong parts, the doors demonstrator for the RACER was recently finalized by LKR Leichtmetallkompetenzzentrum Ranshofen GmbH and Composite Impulse GmbH & Co., including pilot and co-pilot cockpit doors, sideward sliding cabin doors, sideward luggage doors, and backward avionic doors. The doors were created using carbon fiber reinforced polymer (CFRP) manufacturing technologies to meet the mechanical and performance requirements including withstanding high air pressure loads resulting from the cruise speed.

The RACER demonstrator will be assembled and flight tested in 2022.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.