Educating and Engaging End Users in Construction and Infrastructure

ACMA’s Composites Tech Days provide a unique opportunity for members to engage with end users in key markets. This spring, the association will host the Construction/Infrastructure Composites Tech Days on March 7, 14, 21 and 28.

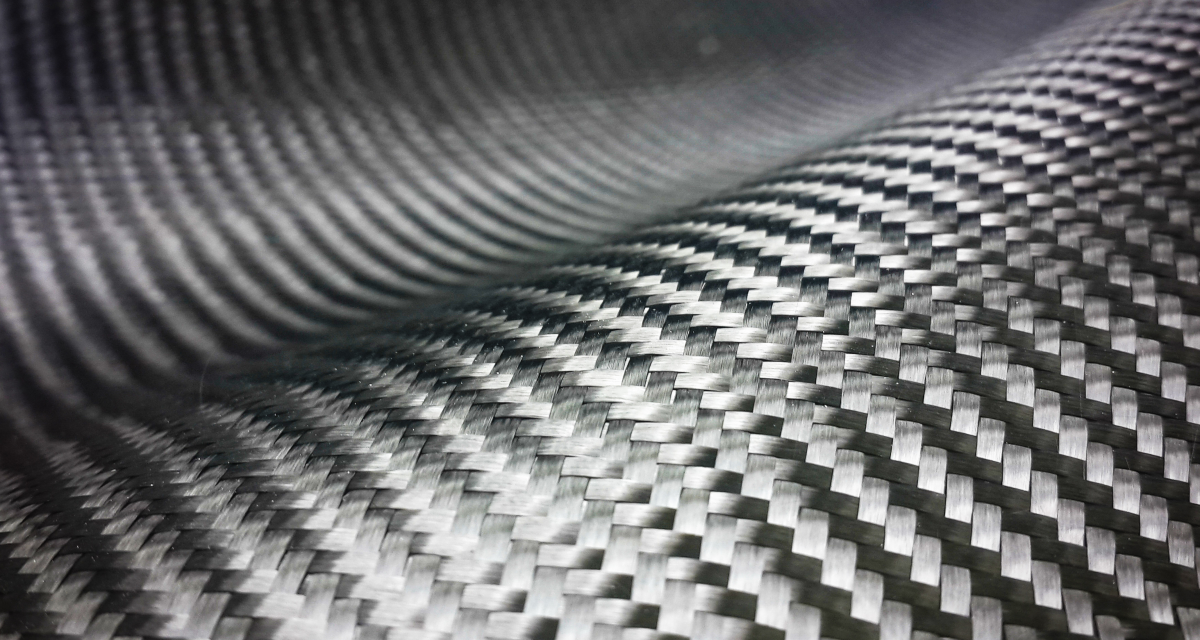

During the virtual event, industry professionals will showcase how composite materials can change the way roads, bridges and buildings are constructed and maintained, offering a longer lifespan and increased durability and resiliency. Attendees will include architects, contractors, designers, engineers, investors, federal and state departments of transportation and other construction and infrastructure professionals.

The lineup includes:

March 7 – Composites for Transportation Infrastructure: The biggest portion of funding in the Infrastructure Investment and Jobs Act is dedicated to roads and bridges. This session will focus on applications for FRP in bridges and designing with FRP girders.

March 14 – Composites for Water & Wastewater Infrastructure and Corrosion-Resistant Applications: Some of the lowest grades in the American Society of Civil Engineers’ most recent Report Card for America’s Infrastructure were assigned to water (C- to D+) and wastewater (D+) infrastructure. This forum will focus on FRP in the water environment, including pipelines, piers, hydraulic structures and inland waterways.

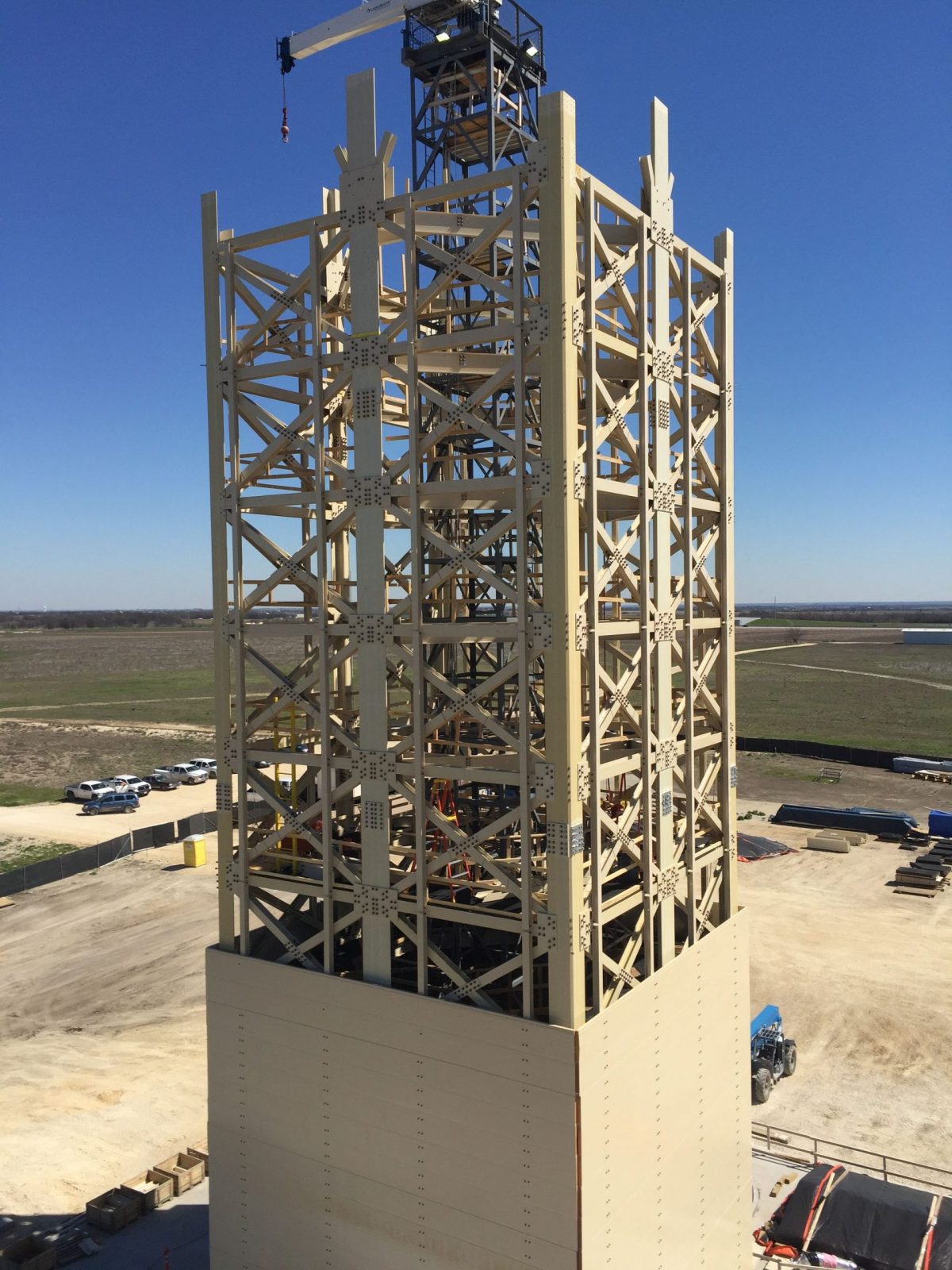

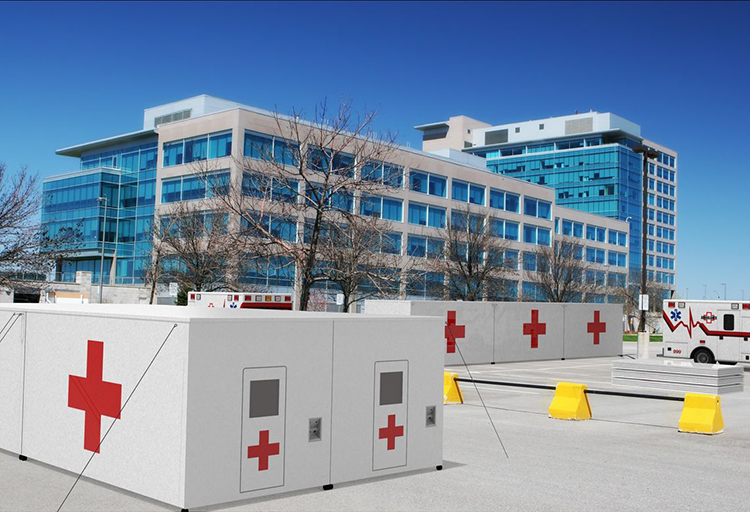

March 21 – Composites for Buildings: Composites are gaining traction for new design and retrofitting of buildings around the world. This session will showcase eye-catching architecture featuring composites, as well as unpack FRP rebar code and its implications for building designers and specifiers.

March 28 – Decarbonization, Durability, Resiliency & Specifications: The final day will feature case studies covering utility poles, seawalls, and flood and earthquake structures to explore the strength and durability of composites. The discussion will also include information on specifications for FRP composites.

For more information on Construction/Infrastructure Composites Tech Days or to register, visit acma.today/c-i-techdays.

SUBSCRIBE TO CM MAGAZINE

Composites Manufacturing Magazine is the official publication of the American Composites Manufacturers Association. Subscribe to get a free annual subscription to Composites Manufacturing Magazine and receive composites industry insights you can’t get anywhere else.